This article analyzes the industrial drivers behind the global dominance of corrugated cardboard, exploring its strategic balance between environmental compliance, material engineering, and logistical optimization. It further examines how specialized manufacturers like Holidaypac leverage these properties to deliver high-performance, cost-effective retail display solutions.

In the current global industrial landscape, corrugated cardboard has transitioned from a traditional packaging material to a strategic asset. While the surge in e-commerce initially catalyzed its demand, its sustained popularity is now driven by a convergence of regulatory pressure, material science advancements, and the demand for agile retail solutions.

For manufacturers and retailers alike, understanding the technical and economic advantages of this material is essential for optimizing supply chain efficiency.

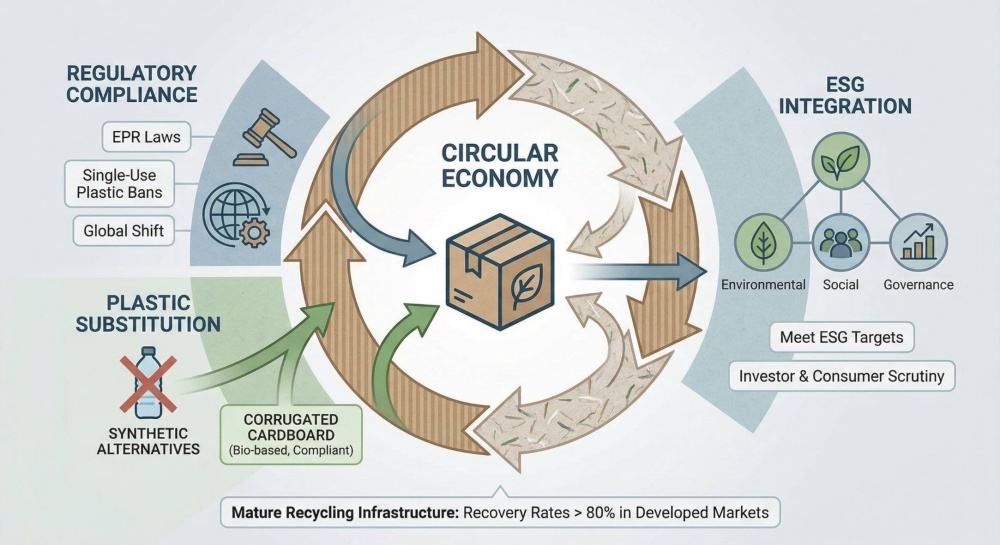

The global shift toward a circular economy has placed corrugated cardboard at the forefront of sustainable procurement. Unlike many synthetic alternatives, corrugated cardboard boasts a mature recycling infrastructure, with recovery rates consistently exceeding 80% in developed markets.

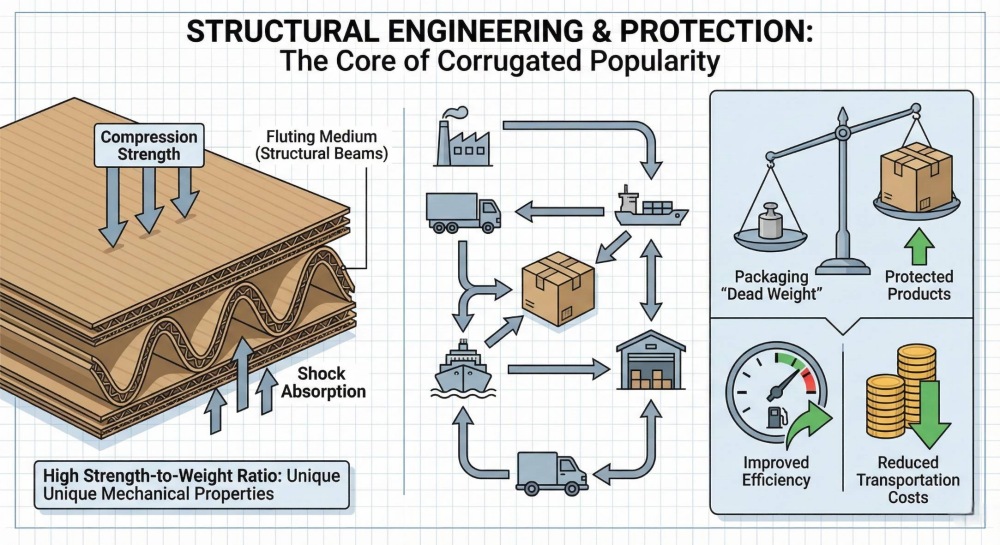

The "popularity" of corrugated cardboard is rooted in its unique mechanical properties. The fluting medium—the arched layer between the liners—functions as a structural beam, providing high compression strength and shock absorption relative to its weight.

This strength-to-weight ratio is a critical factor for logistics. It ensures that products remain protected throughout complex, multi-touchpoint supply chains while minimizing the "dead weight" of the packaging itself, directly impacting fuel efficiency and transportation costs.

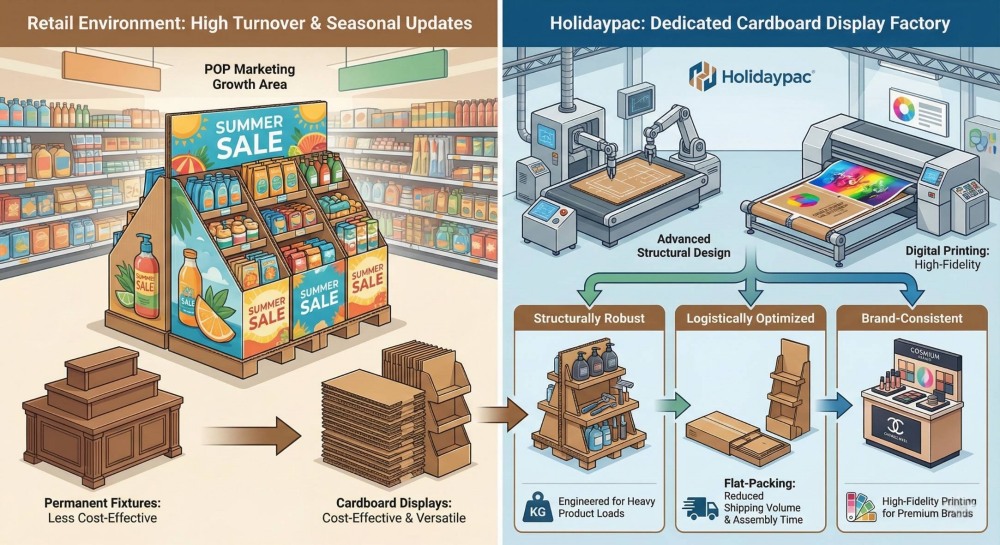

One of the most significant growth areas for this material is in Point-of-Purchase (POP) marketing. Retail environments now demand high turnover and frequent seasonal updates, making permanent fixtures less cost-effective.

Specialized manufacturers, such as Holidaypac, have leveraged these material properties to transform corrugated cardboard into sophisticated retail tools. As a dedicated Cardboard Display Factory, Holidaypac utilizes advanced structural design and digital printing to create high-impact displays that are:

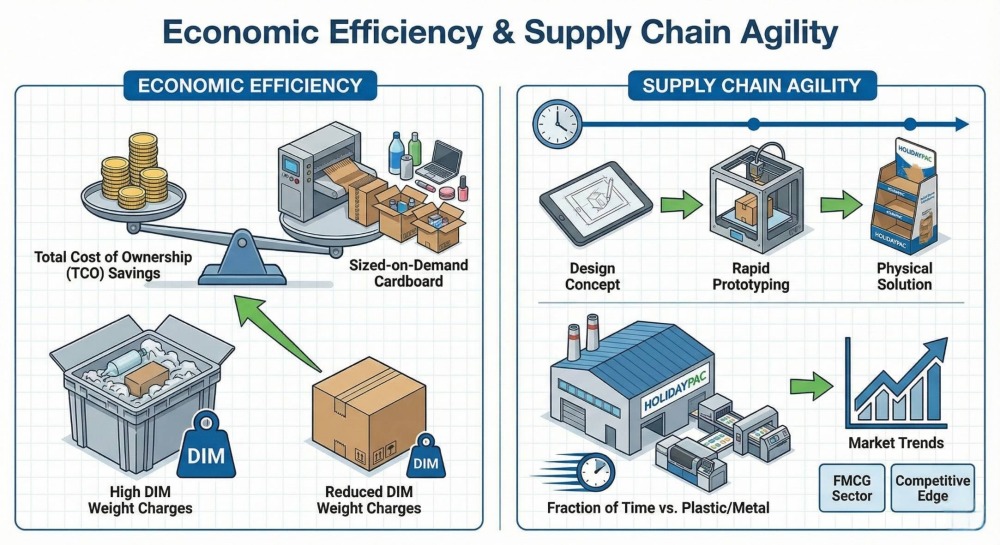

From a Total Cost of Ownership (TCO) perspective, corrugated cardboard offers unparalleled advantages. Its ability to be "sized-on-demand" reduces the need for excessive void fillers, which in turn lowers dimensional weight (DIM weight) charges in logistics.

Furthermore, the rapid prototyping capabilities in cardboard manufacturing allow brands to respond quickly to market trends. Factories like Holidaypac can move from a design concept to a physical display or packaging solution in a fraction of the time required for plastic or metal alternatives, providing a critical competitive edge in fast-moving consumer goods (FMCG) sectors.

The dominance of corrugated cardboard in today’s market is the result of its alignment with modern industrial requirements: sustainability, structural integrity, and economic flexibility. As companies continue to navigate the complexities of green transition and logistics optimization, the strategic use of corrugated materials—supported by specialized partners like Holidaypac—remains a foundational element of a resilient supply chain.

Links