How Costco Display Solutions Are Transforming Retail Merchandising in 2025

Holidaypac

2025-12-22

1789

This article outlines the 2025 Costco merchandising strategy, focusing on Value, Speed, and Sustainability. It highlights how brands must use "ready-to-sell" pallet displays to maximize visual impact while minimizing warehouse labor.

Key Takeaways

- Value Clarity: Use "5-second billboard" design—big type and hero images—to communicate bulk value instantly.

- Operational Speed: Prioritize pre-assembled, "clamp-safe" pallet formats that move from truck to floor with zero touch.

- Sustainability as Savings: Switch to mono-materials and FSC-certified corrugate to reduce recycling fees and disposal time.

- 360° Shoppability: Ensure consistent branding on all four sides to eliminate "dead panels" during high-traffic rotation.

- Compliance & Data: Use GS1-compliant labels and QR assembly videos to prevent receiving delays and setup errors.

In 2025, Costco merchandising prioritizes value, speed, and sustainability. Brands win with bold graphics, pre-packed displays, and eco-friendly materials that improve efficiency and sell-through.

Why Costco merchandising is different in 2025

Costco is a unique high-velocity environment. Wide aisles, bulk formats, and limited SKUs force every display to prove value at a glance. In 2025, three shifts stand out:

- Value clarity beats feature overload. Members scan fast—your price-per-unit, pack size, and hero benefit must be unmistakable.

- Speed-to-floor decides winners. Pre-assembled, clamp-safe pallet displays reduce labor and hit shelves sooner.

- Sustainability is now table stakes. Recyclable materials and clean disposal cut costs, align with member expectations, and support retailer goals.

“Costco-ready” goes beyond strong cardboard. It means:

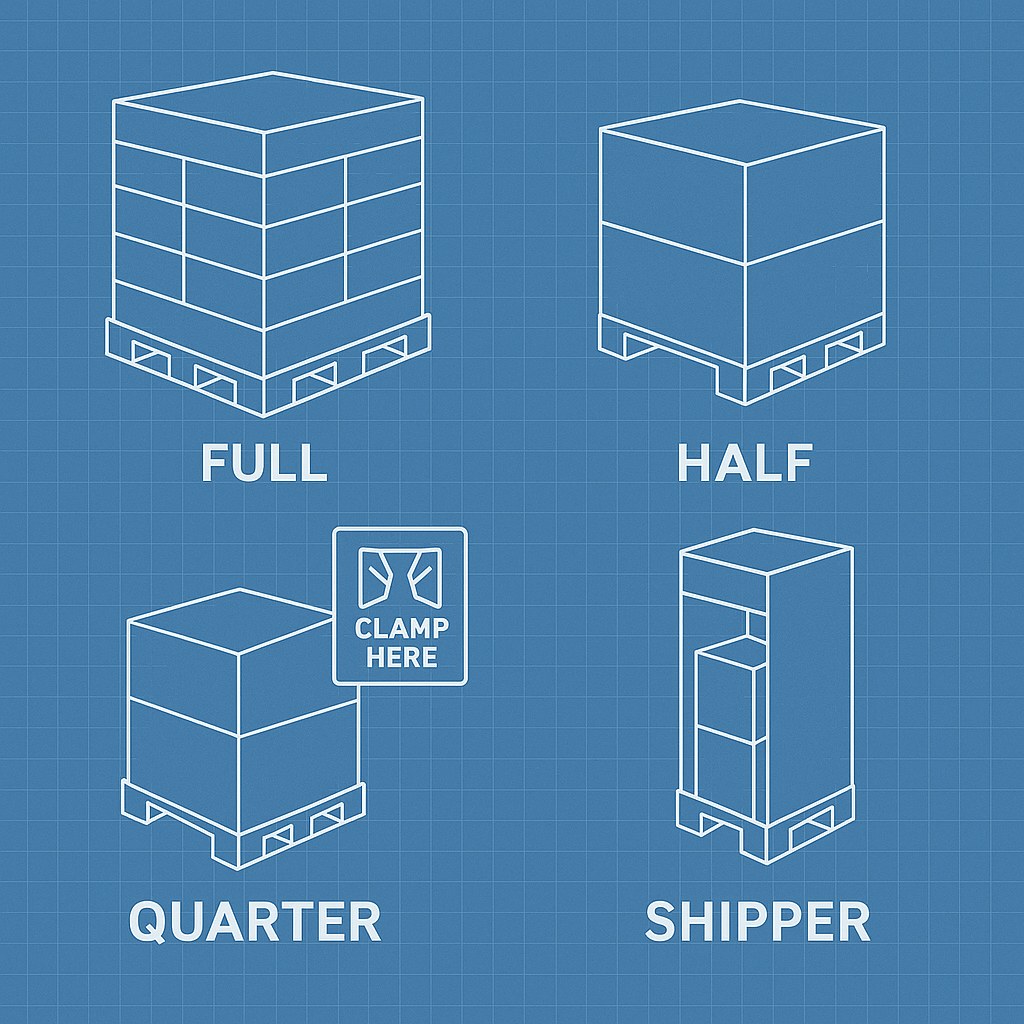

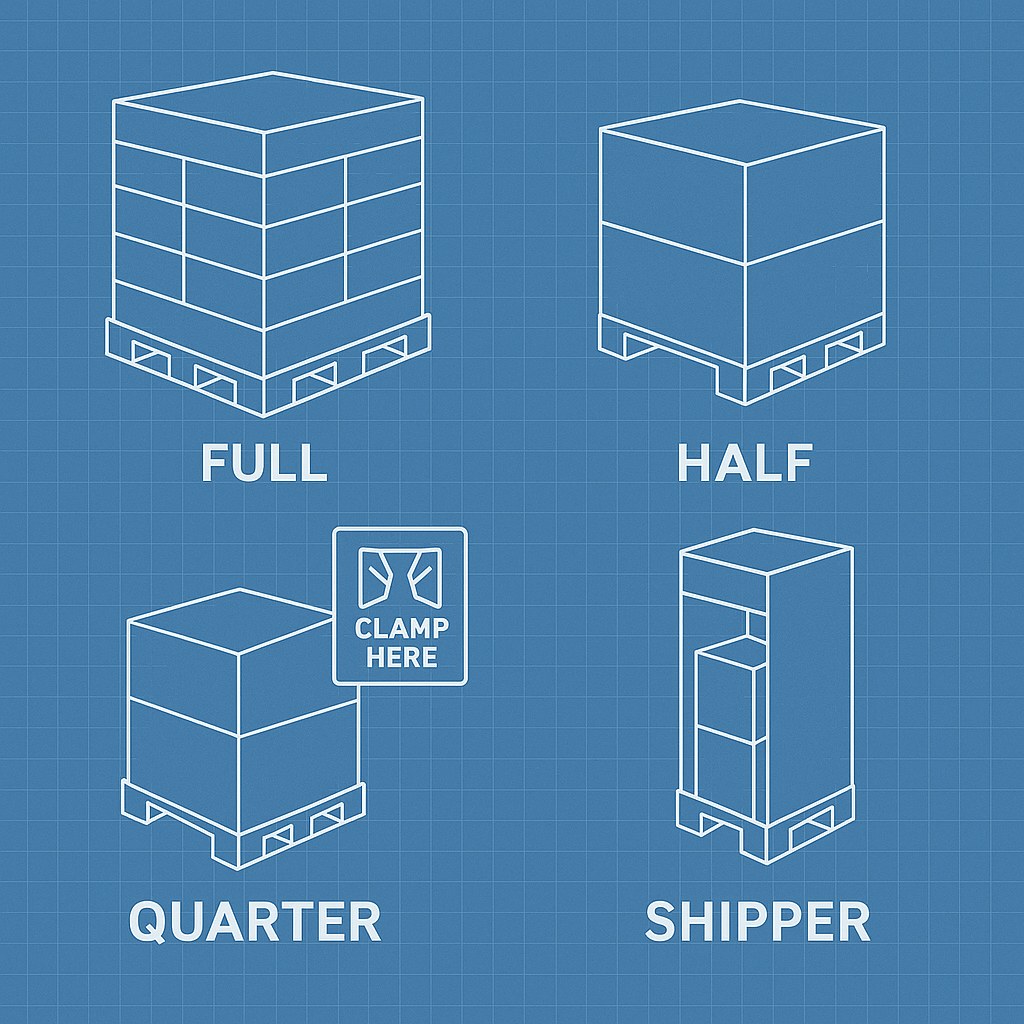

- Pallet-first formats (full, half, quarter pallets; shippers) that roll in and start selling with minimal touch.

- 360° shoppability with consistent messaging on all sides—no “dead panels.”

- Structural accountability: reinforced corners, secure inner packs, and clean edges that survive clamp handling and transport.

- Readable, compliant labeling (unit count, variants, barcodes/GTIN, handling icons) placed where teams expect them.

- Sustainable substrates (FSC-certified corrugate or honeycomb board) that are sturdy, light, and easy to recycle.

Design principles that convert at Costco

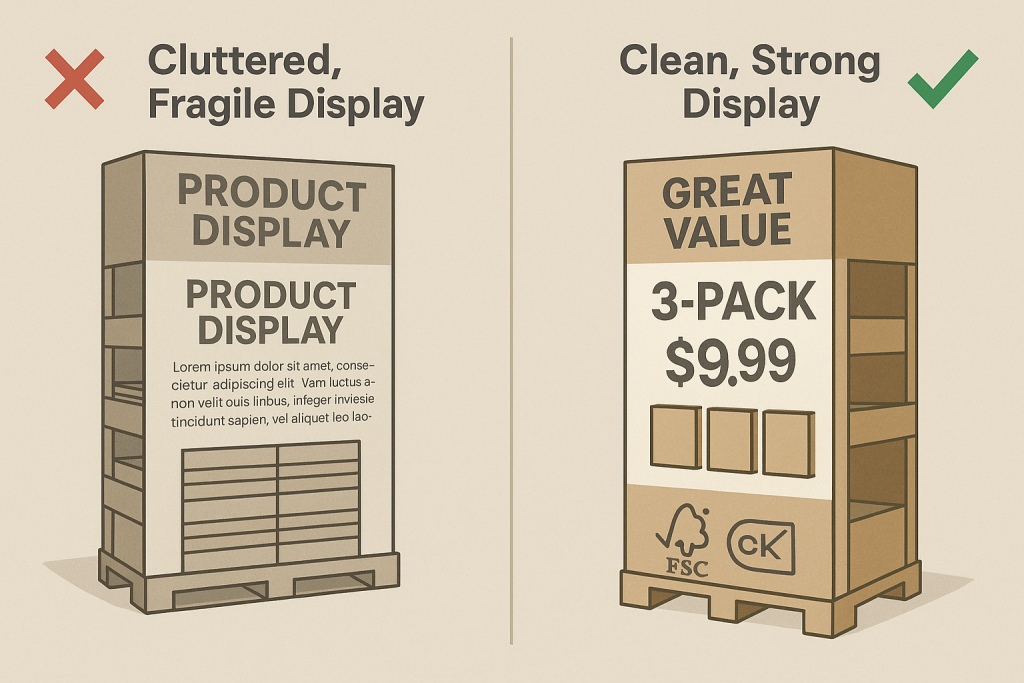

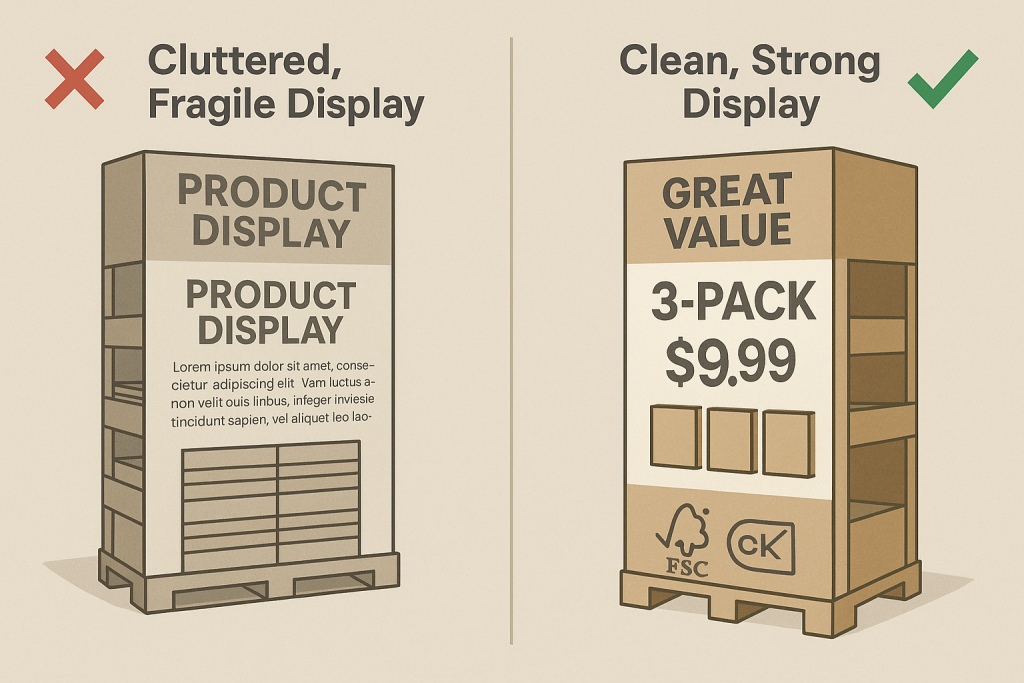

Think “five-second billboard”:

- Big type, big benefit. Use large, high-contrast headlines like “24-Pack Value” or “2-Piece Bundle.”

- One hero image. Avoid cluttered collages; show product scale and usage instantly.

- Price & quantity proximity. Place quantity claims near the price position to reinforce value.

- Color discipline. Two primaries + one accent. Design should pop from 5–10 meters away.

- Iconography that works. “FSC Certified,” “100% Recyclable,” “No Plastic Window,” “Easy Carry Handle”—fast visual cues win.

- No hidden edges. Ensure key claims appear on all four sides for floor re-orientation.

Operations: from warehouse to floor—faster

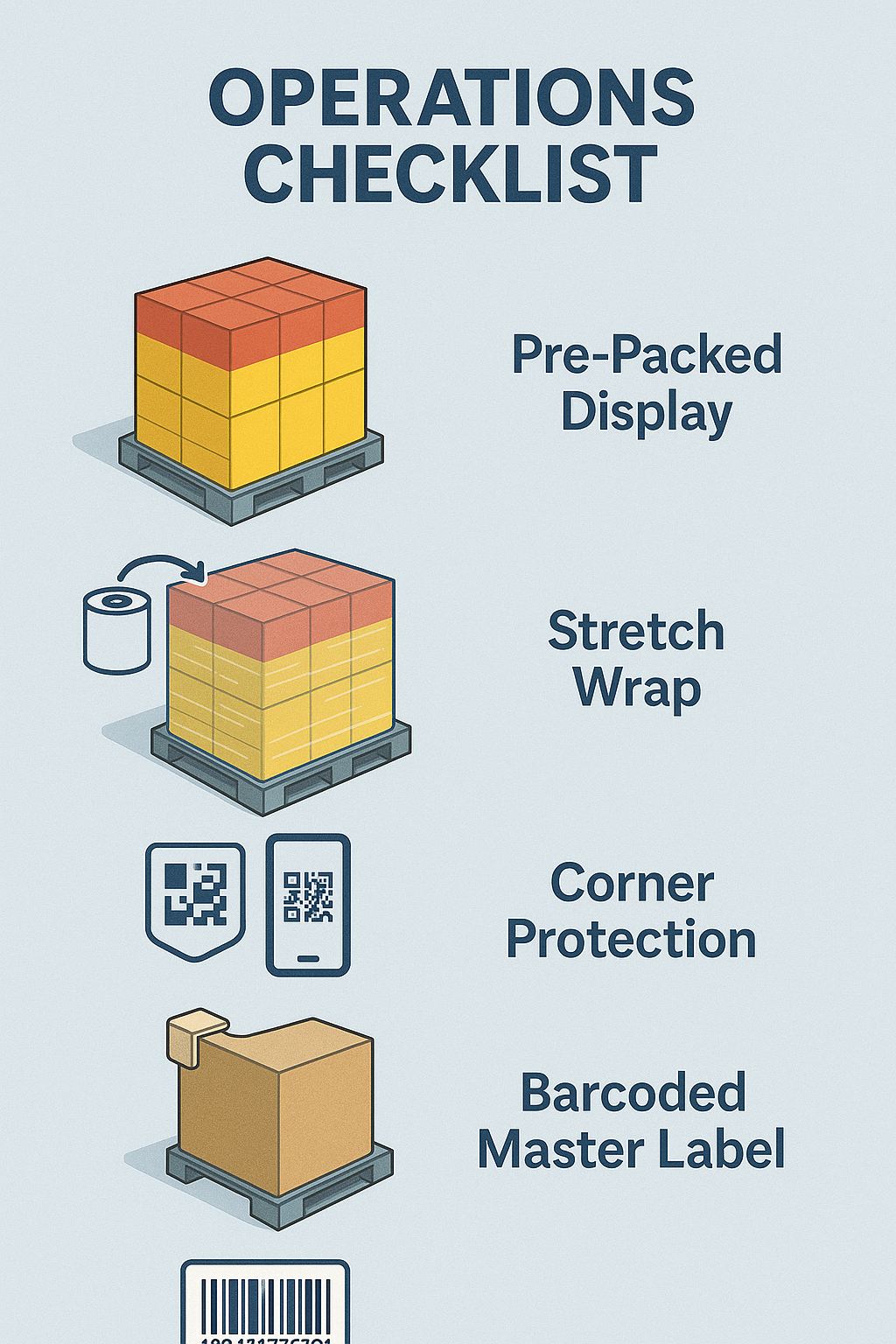

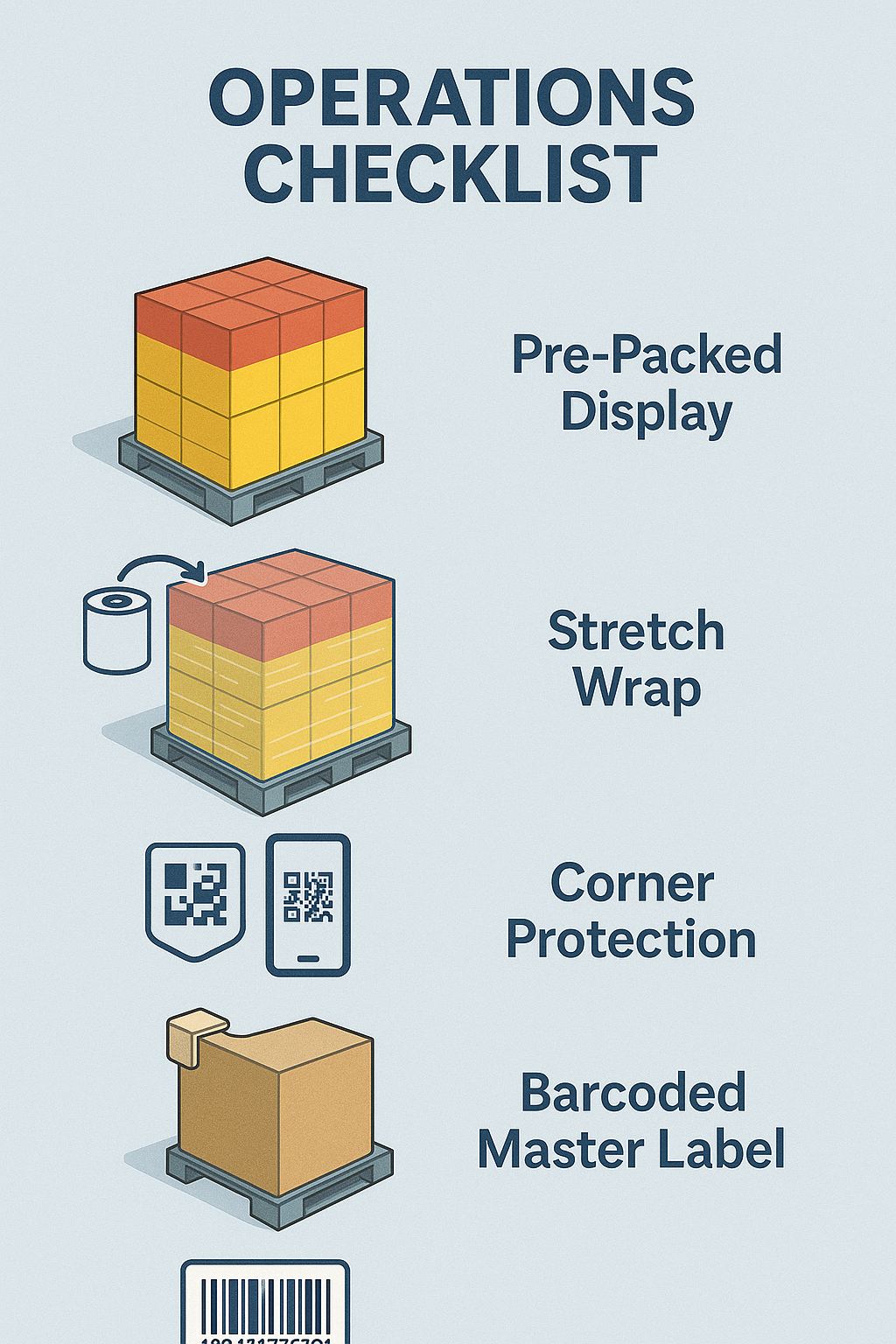

Great displays fail if they’re slow to deploy. In 2025, the ops checklist is your conversion engine:

- Pre-pack & strap smart. Pre-kitted inners, protective corner boards, and stretch wrap that still allows front-panel readability.

- Clamp & forklift friendly. Clear “Clamp Here”/“Do Not Clamp” zones, handling pictograms, and robust corner strength.

- GS1-compliant labeling. Clean master labels and scannable barcodes on the same face—avoid hunt-and-peek receiving.

- Assembly minimized. If something must be folded on-site, include QR video and one-page pictograms.

Sustainability that lowers total cost

Sustainability isn’t just a badge—it’s a TCO lever:

- Right-weighting. Use the lightest flute/grade that passes your drop/compression tests.

- Mono-material design. Ditch plastic windows and foam; simplify recycling and reduce fees.

- Ink coverage discipline. Strategic solids + line art = premium look, faster drying, less smudging.

- Certifications that matter. FSC chain-of-custody on paperwork and artwork. Members notice—and so do buyers.

Data-smart iteration (without overcomplication)

You don’t need a lab to learn:

- A/B by club region or season. Test two headlines or pack counts; track weekly sell-through and replenishment cadence.

- Operator feedback loop. Ask receiving and floor teams what slowed them down—then remove those steps.

- Returns analysis. Rework weak corners or tear-outs before scaling the next run.

Common mistakes to avoid

- Wall-of-text panels. If members must read a paragraph, you’ve already lost.

- One-side design. Displays get rotated; keep claims on all faces.

- Pretty but fragile. Structural failure wipes out all design gains.

- Over-SKUing a shipper. More choice = slower shopping and messier replenishment.

- Ignoring disposal. If teardown is hard, stores resist re-orders.

FAQs

1) What size pallet display performs best at Costco?

It depends on velocity, price point, and replenishment. Many brands start with quarter or half pallets for speed and learnings, then scale.

2) Can I mix multiple SKUs in one shipper?

Yes—keep it tight (ideally one or two variants). Over-mixing slows the shop and creates messy shelf recovery.

3) How important is sustainability on the artwork?

Very. Clear recycling and FSC cues build trust and can lower total cost through simpler materials and disposal.

4) Do I need assembly videos?

If any step remains on-site, a QR quick-start video reduces training time and errors—worth the tiny cost.

5) What’s the top mistake brands make?

Under-estimating operations. Even stunning design fails if it’s slow to receive, hard to move, or fragile on floor.