POP vs. PDQ Displays: What’s the Difference?

Holidaypac

2025-10-25

1459

If you sell into modern retail, you’ll hear two terms all the time: POP and PDQ. They’re related—but not the same. This guide breaks down what each means, where they’re used, and how to choose the right cardboard display for your product and budget.

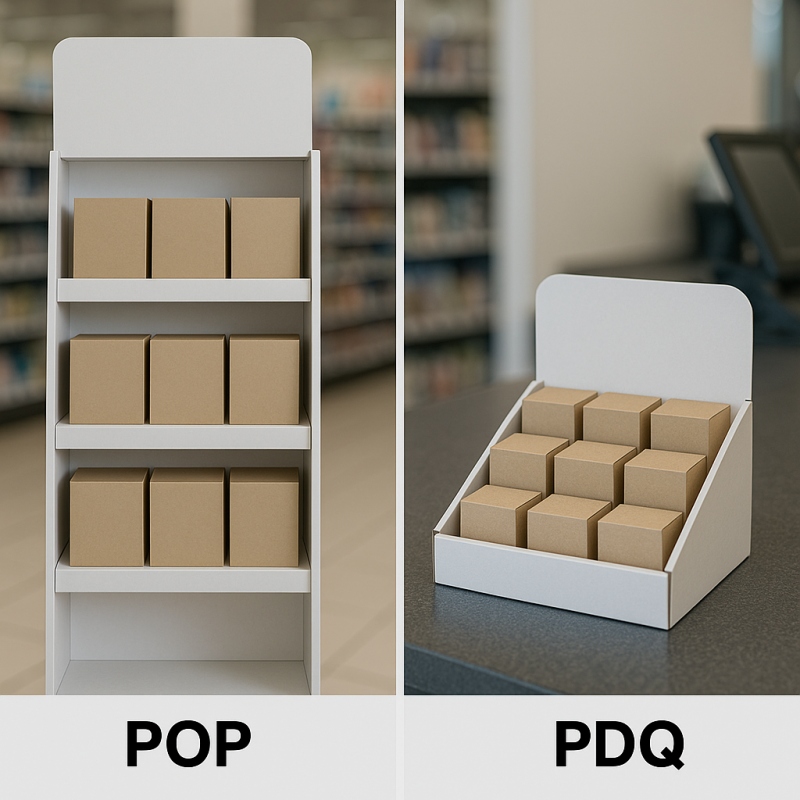

Quick definitions

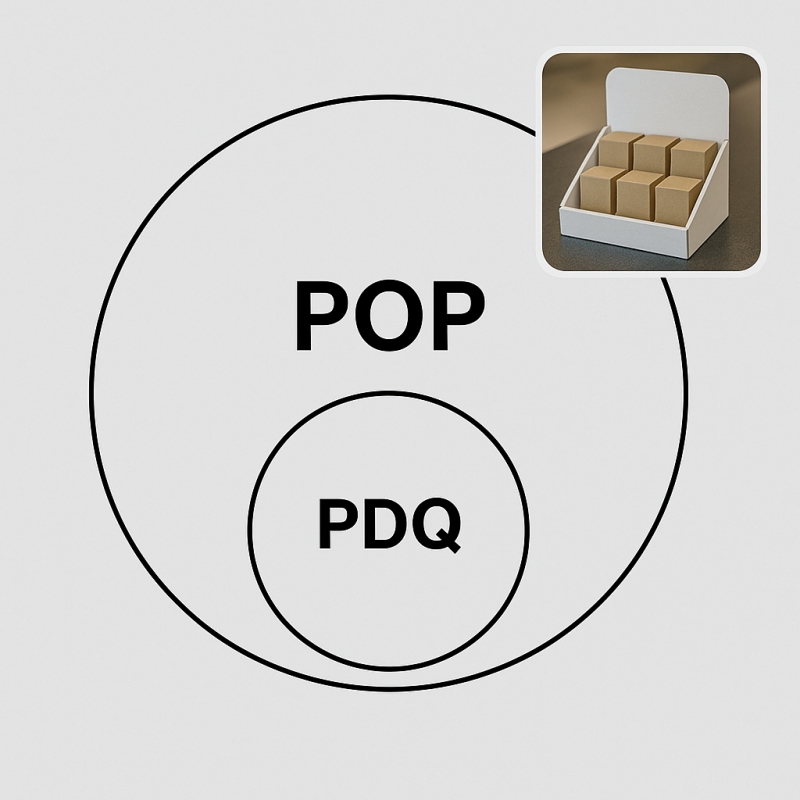

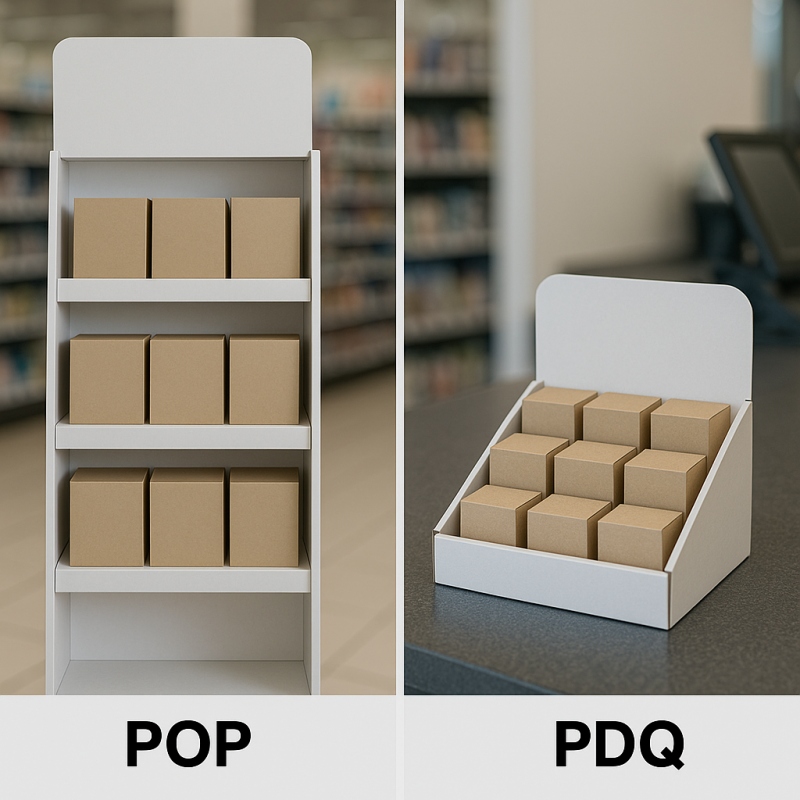

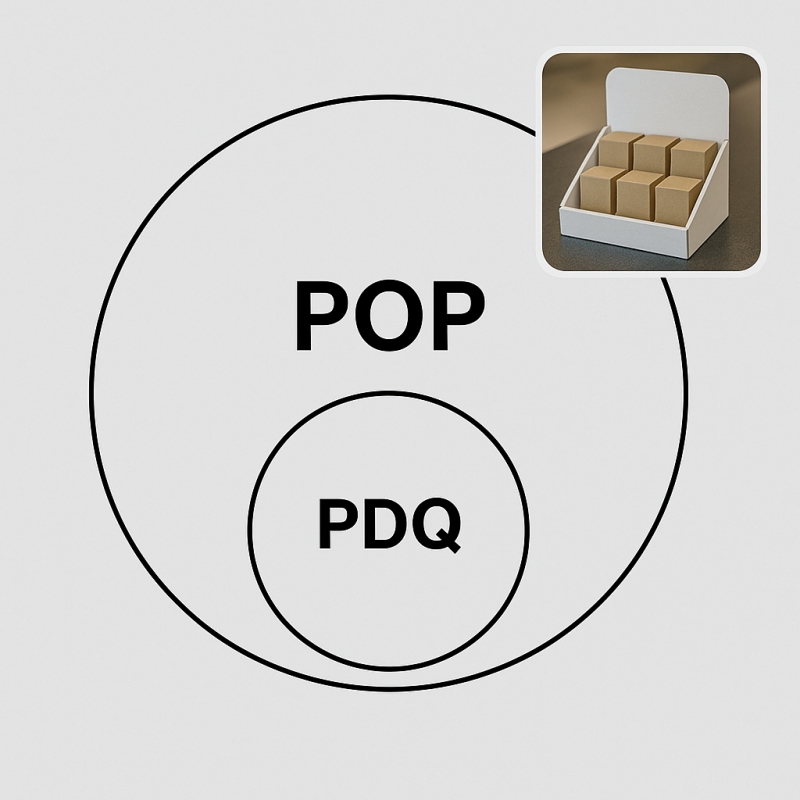

- POP Display (Point-of-Purchase):An umbrella term for any in-store promotional display placed where the shopper decides to buy—end caps, floor stands, dump bins, pallet displays, counter units, sidekicks, etc.

- PDQ Display (“Pretty Darn Quick” / “Quick-set Counter or Shelf Display”):A compact, usually pre-packed counter or shelf unit designed for fast setup. Think candy, lip balm, travel-size cosmetics, batteries, or seasonal add-ons near the register.

In short: All PDQs are POP displays, but not all POP displays are PDQs.

POP vs. PDQ at a glance

| Feature |

POP Display (umbrella) |

PDQ Display (subset) |

| Best for |

Launches, promotions, brand blocks, larger assortments |

Small SKUs, impulse buys, trial sizes |

| Typical placement |

Floor, aisle, end cap, pallet, checkout, sidekick |

Checkout counters, shelves, reception areas |

| Capacity |

Medium–High |

Low–Medium |

| Pack-out |

Often packed empty + store fill |

Frequently pre-packed to save time |

| Setup time |

Varies (5–30 minutes) |

Very fast (1–5 minutes) |

| Unit cost |

Wider range |

Usually lower |

| Shipping |

Bulky if large formats |

Compact master cartons |

| Lifespan |

4–12+ weeks |

2–8 weeks |

| Common materials |

Corrugated cardboard, honeycomb board, board + PVC hooks |

Corrugated cardboard, light board |

When to choose each

Choose PDQ if you need:

- Speed at scale: hundreds of stores, each with a 1–5 minute setup

- Small items: lipsticks, sachets, mini treats, trial kits

- Tight spaces: checkout areas or narrow shelves

- Cost control: compact shipping, streamlined replenishment

Choose a POP (non-PDQ) format if you need:

- Big visual impact: full-height floor stand or pallet display

- Multiple SKUs or stories: routine steps, shade families, bundles

- Category blocking: claim space and improve navigation

- Longer campaigns: sturdy build for months on the floor

Design checklists

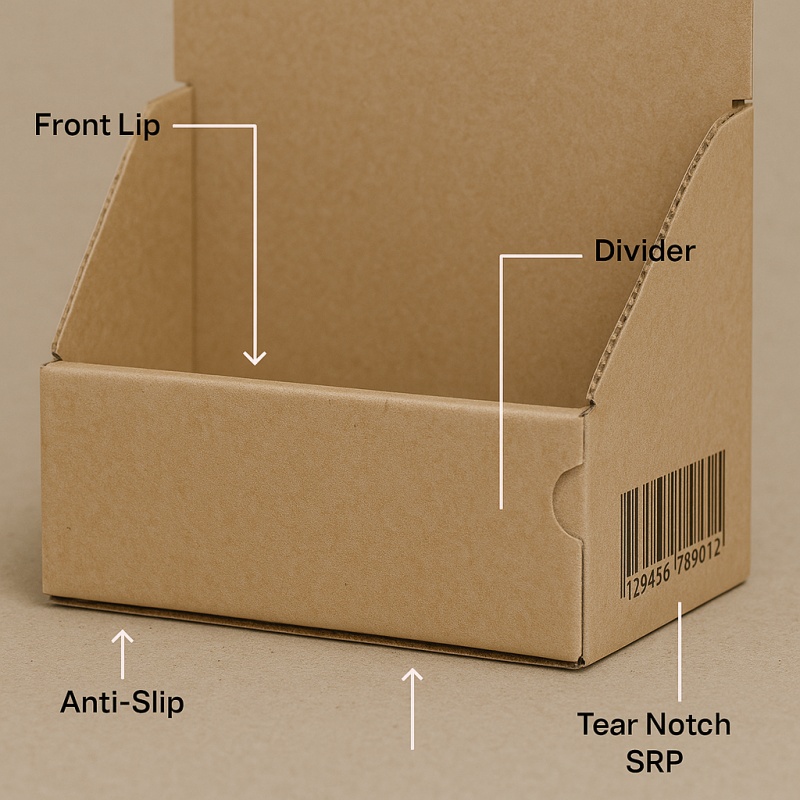

Winning PDQ (counter/shelf) checklist

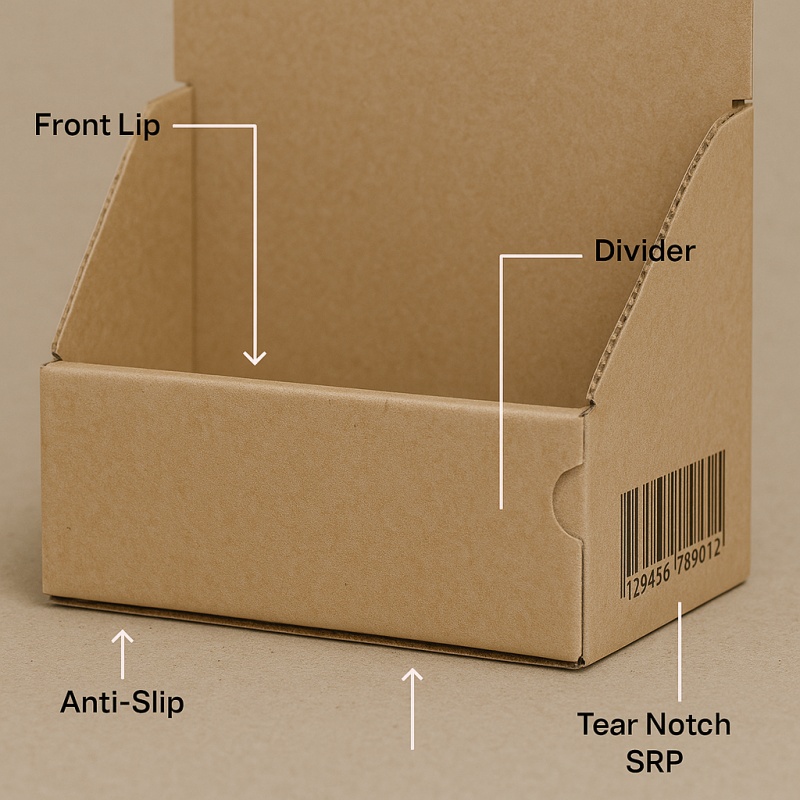

- Footprint first: Confirm shelf depth and height stop; design to fit without overhang.

- Front lip & dividers: Keep packs tidy and readable; add a small lip to prevent slide-out.

- Refill fast: Use simple trays or tear-away SRP (shelf-ready pack) for quick restock.

- Clean branding: One strong headline, one benefit, one CTA.

- Compliance: Check retailer size, safety, and barcode rules before sampling.

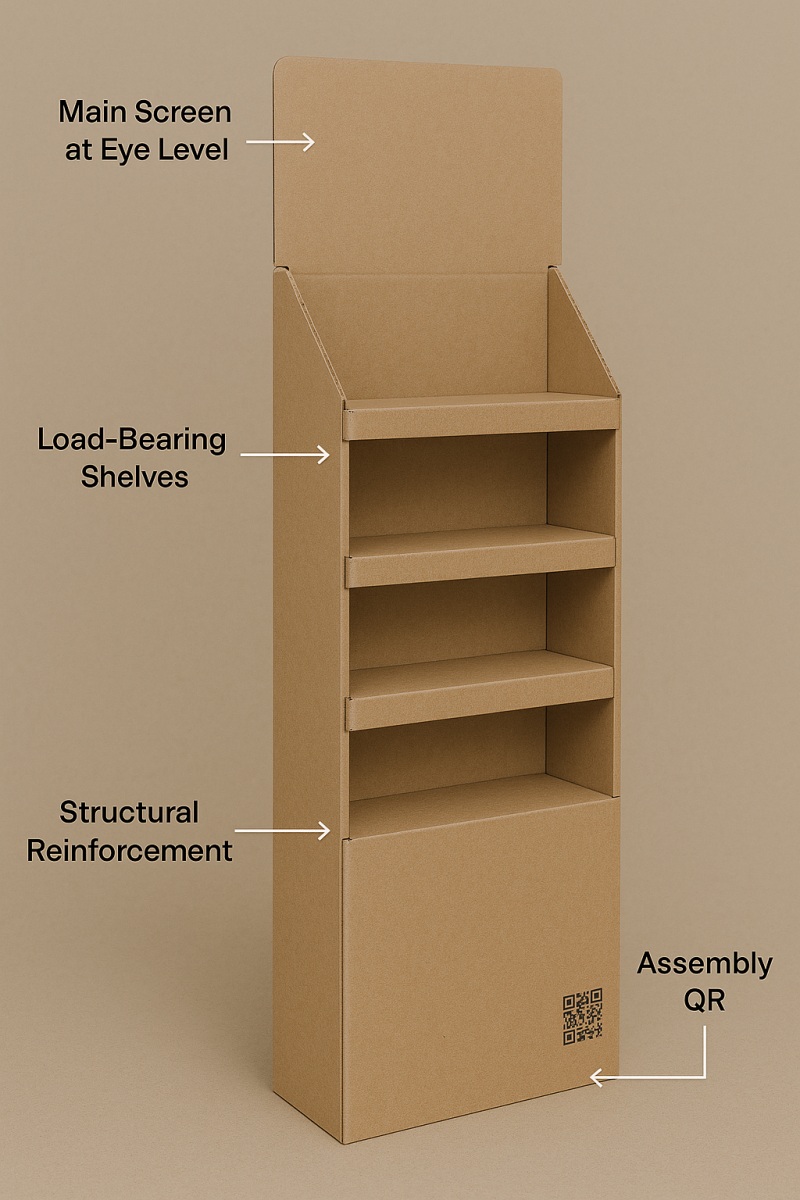

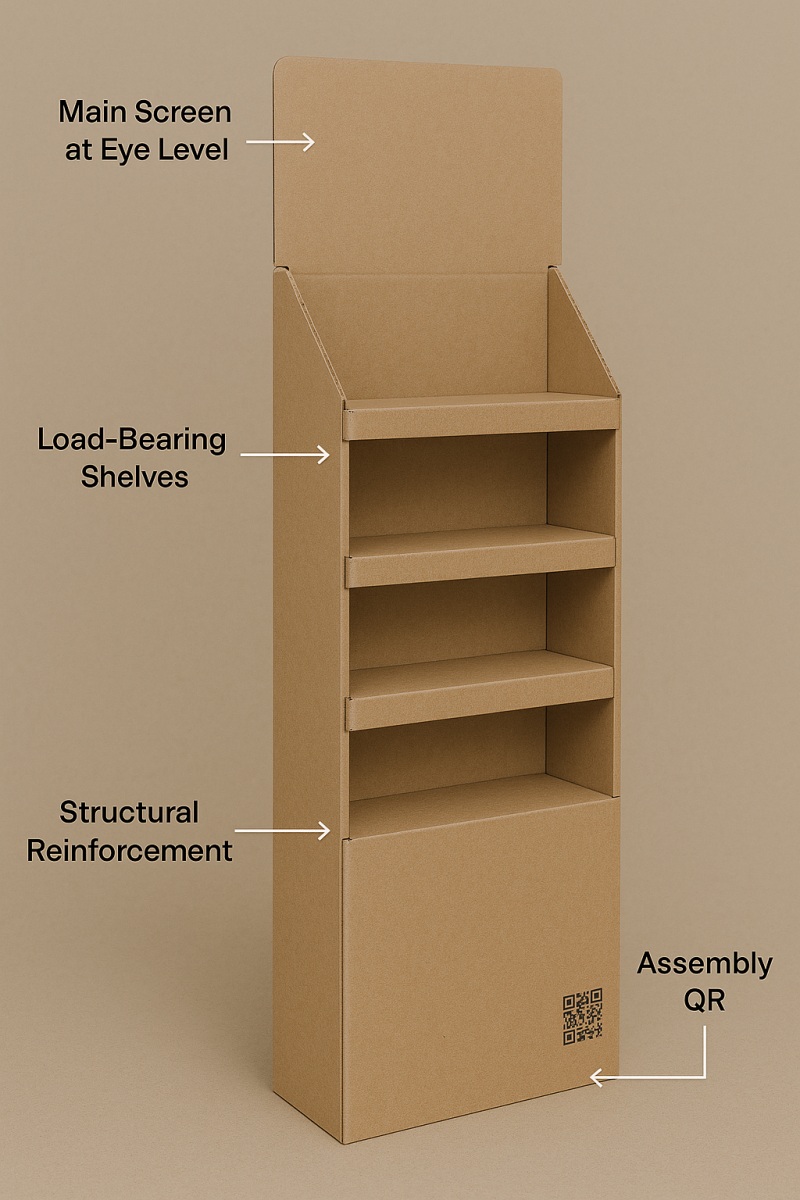

Winning POP (floor/pallet) checklist

- Shopper flow: Hero branding at eye line; keep reach zones comfortable.

- Structure: Match load to board grade; test shelf deflection with real product weight.

- Graphics: Big from afar, clear up close; use 1–2 claims, not five.

- Assembly guide: Step-by-step QR or printed pictorial reduces store calls.

- Logistics: Flat-pack efficiently; confirm pallet pattern and height caps.

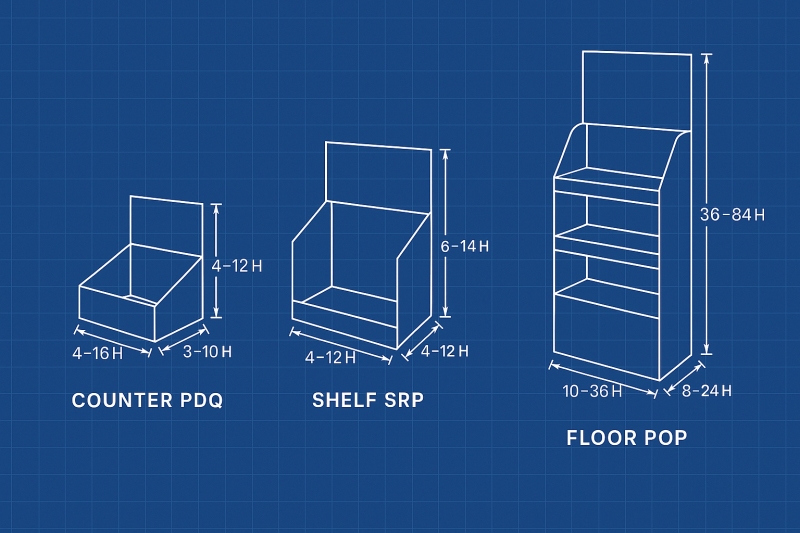

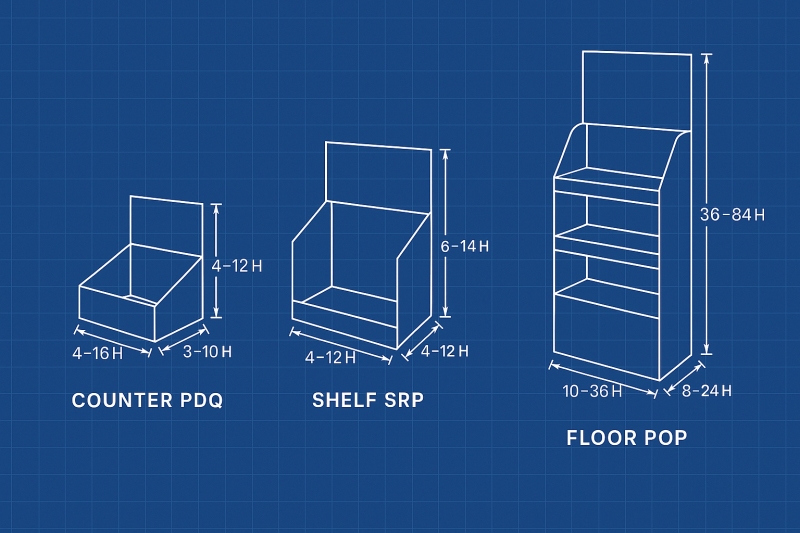

Sizing cheatsheet (typical, not strict)

Cost & operations tips

- Pre-pack to save labor: PDQs that arrive display-ready reduce store time and errors.

- Optimize board grade: Don’t over-spec; use testing to validate the lightest safe grade.

- Ink strategy: Heavy solids add cost and scuff risk—use negative space smartly.

- Bundle spares: Include a spare header or tray for long runs to extend life.

- Plan replenishment: For PDQs, add a matching refill SRP to keep sell-through high.

Real-world use cases

-

Beauty minis: PDQ at checkout for seasonal shades; floor POP for full regimen story.

-

Snack launches: Quarter-pallet POP for awareness; PDQ near coffee machine for impulse.

-

Pharmacy: PDQ for travel OTC items; sidekick POP for accessories near category.

Compliance & sustainability

- Retailer rules first: Dimensions, ticketing, barcodes, safety, aisle clearance, and pallet caps vary by chain. Get the PDF, design to spec, and sample early.

- Eco-friendly options: FSC board, water-based inks, minimal lamination, mono-material designs for easier recycling.

How Holidaypac can help

As a factory partner, Holidaypac offers OEM/ODM, fast sampling, and flexible MOQs for North America, Australia, and beyond. Whether you need a display-ready PDQ or a high-impact floor POP, we optimize structure + graphics + logistics so your sell-through improves—and your stores love the setup.

Need a recommendation? Share your SKU size, target retailer, placement (counter/shelf/floor), and expected weeks on display. We’ll propose 2–3 structures with cost and lead-time options.

FAQs

Q1: What does “PDQ” actually stand for?

In retail packaging, PDQ commonly refers to a quick-set, compact counter or shelf display that’s either pre-packed or very fast to assemble.

Q2: Can a PDQ hold multiple SKUs?

Yes—use dividers or small wells. Keep the assortment simple so shoppers don’t hesitate.

Q3: Are PDQs only for checkout?

No. They also work on shelves, service counters, and reception areas—anywhere you need tidy, small-footprint merchandising.

Q4: Can POP displays be eco-friendly?

Absolutely. Choose FSC certified corrugate, water-based inks, and avoid plastic windows where you can.