When I first started working with Phunkshun Wear on their balaclava and neck tube packaging, the goal sounded simple: make sure every single piece of packaging is fully REACH & Prop 65-compliant.

But if you've ever done packaging exports to North America and Europe, you'll understand that compliance is never a simple matter.

It turns into a careful, deliberate process.

And sometimes, a reality check.

This is the story of how our Holidaypac team built a compliance-first workflow and delivered packaging that passed every single chemical safety test—from 250 SVHC substances under REACH to lead, cadmium, and phthalates under California Proposition 65.

All with documented evidence.

All with zero detected harmful substances.

All confirmed by an independent, globally recognized lab.

Phunkshun Wear sells ski and outdoor gear across Canada, the U.S., and Europe.

Their packaging needs to cross borders smoothly, avoid customs red flags, and align with internal sustainability and consumer-safety commitments.

For them, “good packaging” wasn’t just about print quality or structure.

It was about ensuring every substrate—paperboard, printed layer, coating, glue—stood up to extremely strict regulations.

Specifically:

A European regulation controlling chemicals in materials. The high-risk substances are called SVHC — Substances of Very High Concern.

A U.S. state law warning consumers about chemicals known to cause cancer or reproductive harm.

These aren’t optional checkboxes.

They are legal requirements.

And because Phunkshun Wear distributes internationally, compliance had to be airtight.

I’ve learned one simple truth over years of doing this:

Compliance cannot be added at the end. You have to start with it.

So we built the packaging process with compliance in mind from day one.

Every paper, board, coating, and ink was pre-screened.

We requested MSDS sheets, verified supplier compliance claims, and eliminated materials with potential SVHC or heavy-metal risks.

Before external testing, we conducted our own risk assessment to ensure no known restricted substances could appear in:

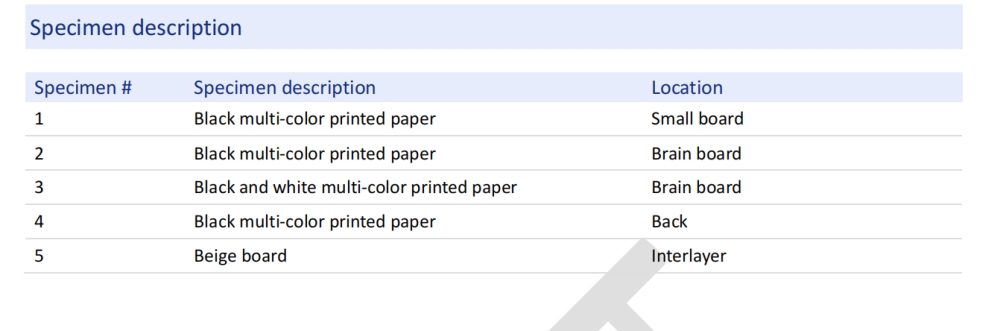

Finally, we sent 3 pieces per style to QIMA Testing (Shanghai) — a well-known global compliance testing company — for full chemical analysis.

This is where things become real.

Labs don’t care about print quality or deadlines.

They report what they find.

And what they found was… nothing.

Which in compliance terms is the best possible result.

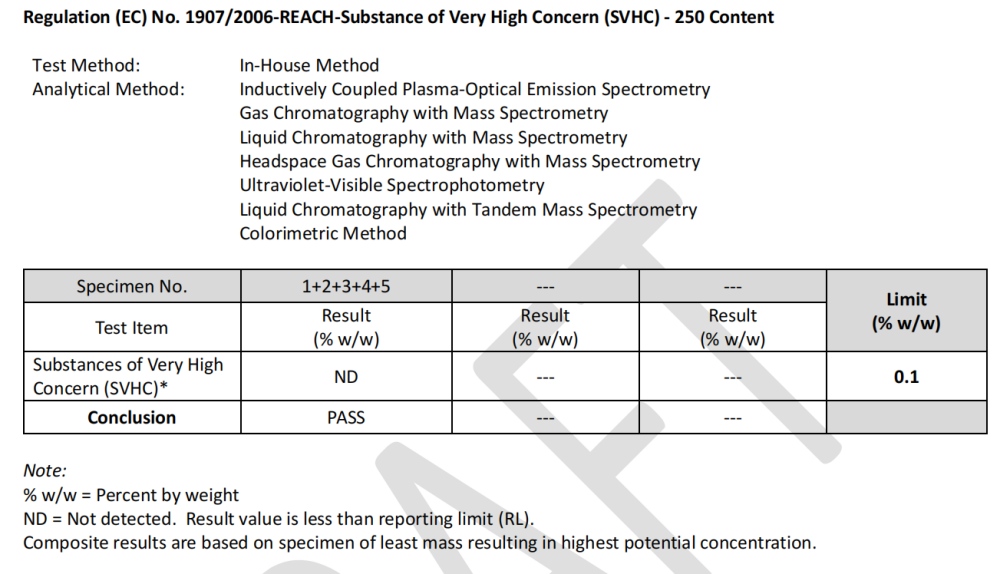

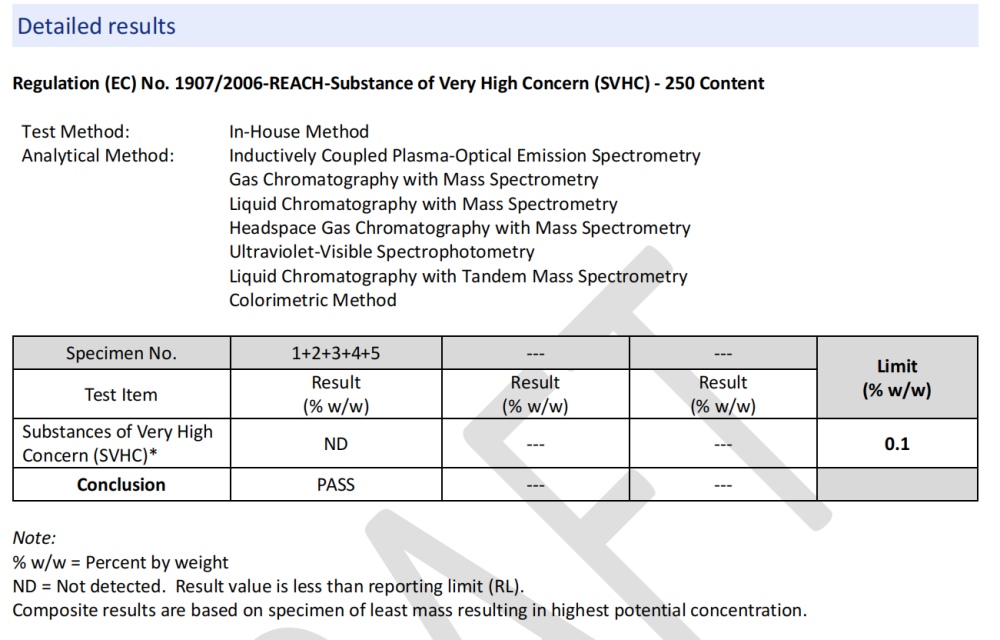

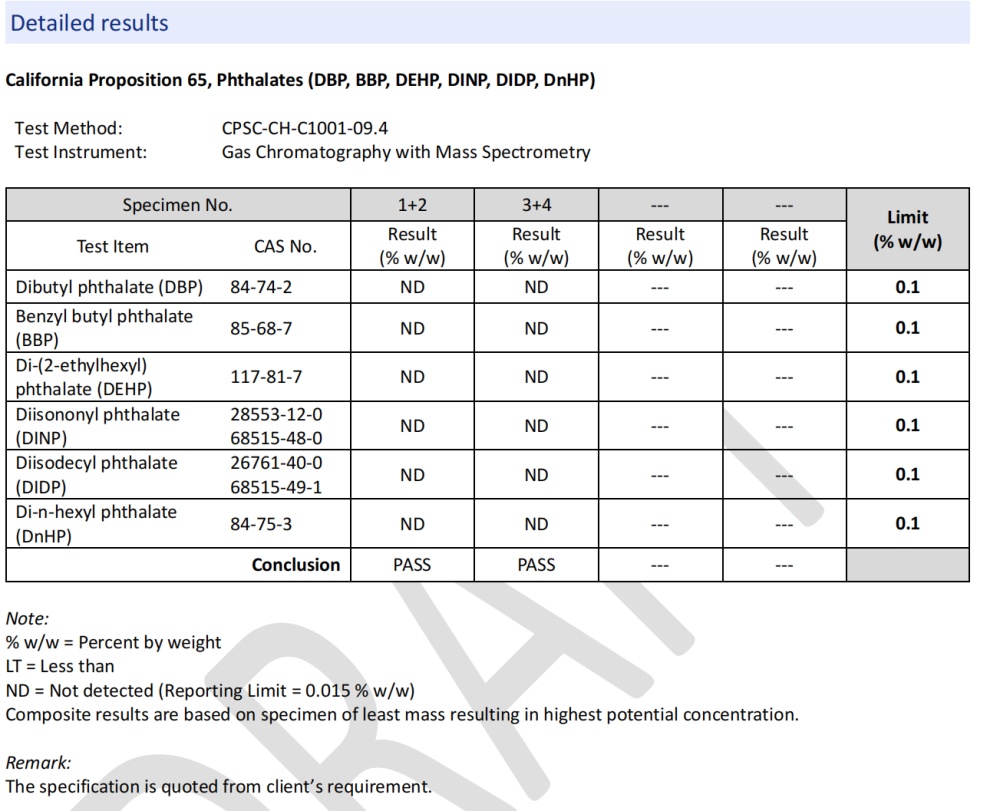

The most demanding part of the test was the REACH SVHC assessment, covering 250 controlled substances.

QIMA confirmed zero detection of all SVHC substances (ND = Not Detected) with limits at 0.1% w/w.

Even after:

For context:

Many brands fail SVHC because of inks, adhesives, or coatings.

So for all composite samples to show ND across the board is a strong indicator that our raw-material control system works.

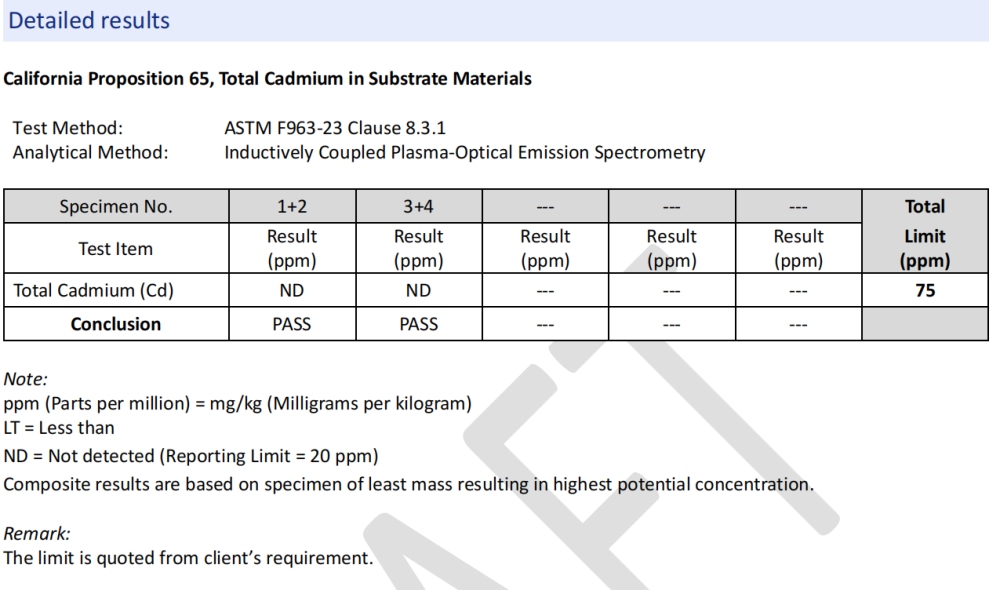

California Prop 65 is known for being one of the most stringent chemical regulations in the world.

Here’s how our materials performed:

Six key plasticizers restricted by Prop 65 were tested:

Every single result: ND

Limit: 0.1% w/w

These tests matter because phthalates commonly appear in coatings and laminations. Passing all categories proves the material stack is free from hidden risks.

When I share compliance results with customers, most people immediately ask:

“So does ND mean it’s completely safe?”

Here’s the down-to-earth version:

For Phunkshun Wear, this means:

And for Holidaypac, it reinforces something we care about deeply:

Compliance builds long-term relationships.

Every project teaches something.

This one reinforced a few truths:

Some brands assume that if the packaging is paper-based, it's naturally safe.

Not true.

Inks, adhesives, coatings, and recycled fibers can all contain restricted chemicals.

Certifications from suppliers help, but third-party testing is the gold standard.

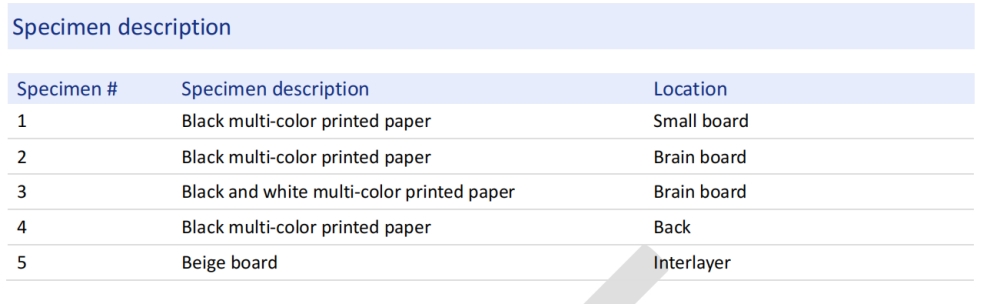

It wasn’t just one layer that passed—five different material components all cleared the tests .

That consistency doesn’t happen by accident.

Retailers increasingly demand verified chemical safety.

Having complete documentation helps brands scale confidently.

If you’re in the outdoor, apparel, food, beauty, or consumer-goods industry, and your products sell globally, you'll eventually need:

This case proves one thing:

When compliance is built into the manufacturing process, testing stops being a gamble.

Holidaypac didn’t “hope” the packaging would pass.

We engineered it to pass.

And Phunkshun Wear now has fully documented proof for any distributor, retailer, or regulatory authority.

This project wasn’t simply about printing packaging.

It was about removing friction—from customs, from regulators, from risk.

By working closely with Phunkshun Wear and validating every detail through QIMA’s independent testing, we delivered fully REACH & Prop 65-Compliant Packaging that stands up to real-world scrutiny.

If you're navigating complex compliance requirements, my suggestion is simple:

Start early.

Work with partners who take compliance seriously.

And never wait until production is finished to think about testing.

Because compliance is not a line item.

It’s peace of mind.

In this page, HolidayPac will show the cases how holidaypac supply the packaging and cardboard displays and other related products solution for our clients. To save the communicated time cost and make the solution in a high effect to save our clints time cost. HolidayPAC try to be a global packaging factory, solution expert in paper and paper related products, like, paper packaging, cardboard displays, PDQ, and air fryer liners, pharchment papers.

Links