All of our bespoke packaging boxes offer excellent levels of insulation, so no matter what your product is, simply choose the insert that suits your specific needs. Each one is made from our own paper honeycomb and board sheets, and manufactured to our exacting standards. For standard insulation at a great price, the easily installed 4 Piece insert offers all the insulation and protection you will need for a wide variety of everyday products. We have many stringent procedures we adhere to in order to maintain our high level of service, two of which have been at the forefront of the business from the outset; the quality of our products and the passion and skill of all of our workforce. Over the years we have developed and refined all of our products to perform to their best, allowing us to offer innovative, reliable, cost-effective and technically sound products with extremely high sustainability credentials.

Combine all of this with the investment in both our technology and our workforce and we have a winning formula that has stood the test of time. ABOUT OUR TEAM

Incredibly versatile boards from a business with a genuine commitment to sustainability

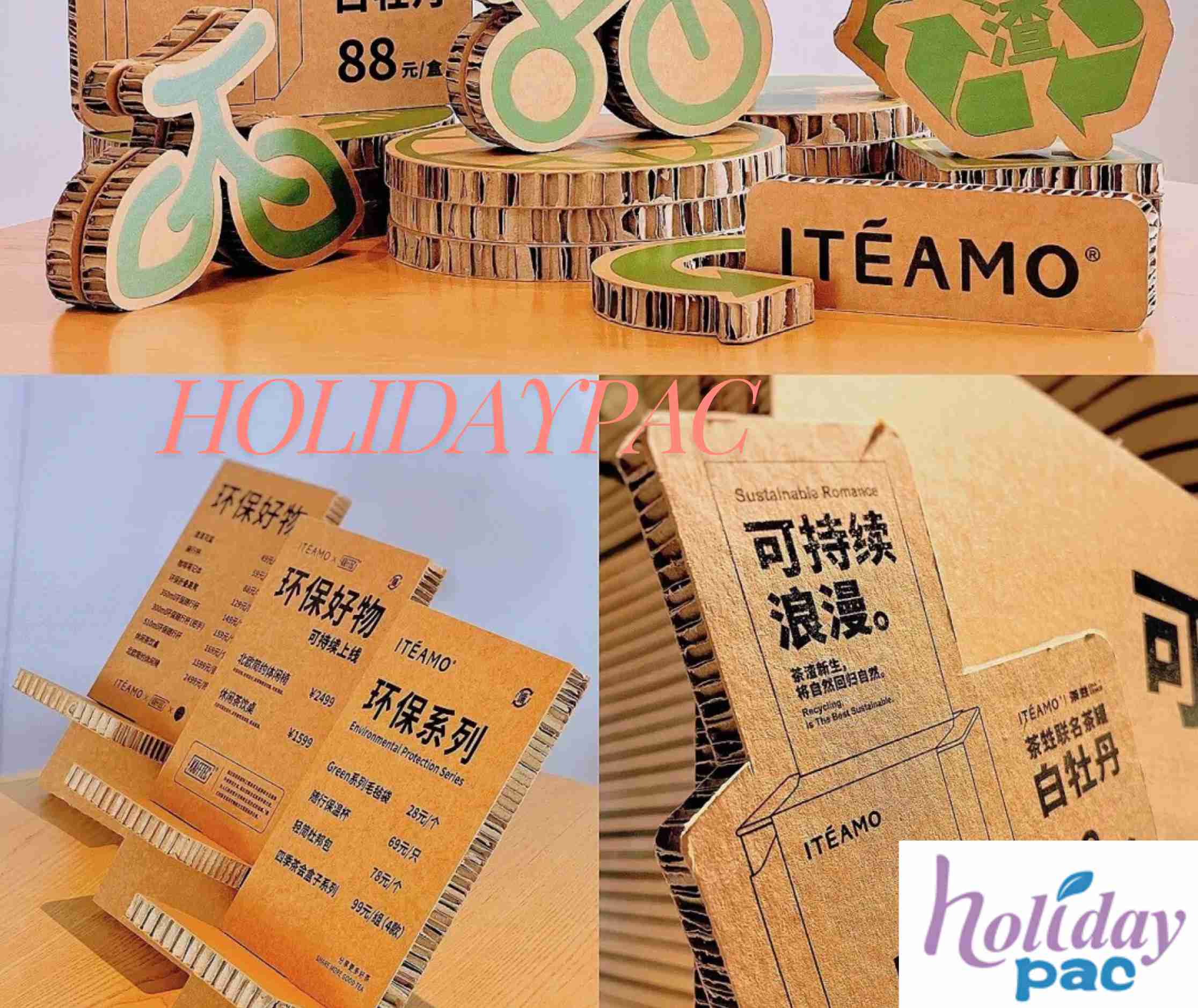

Through many years of research and development, Dufaylite now designs and manufactures a range of innovative, sustainable and environmentally friendly paper honeycomb and board solutions that suit the green credentials of many businesses in a large number of sectors. Our lightweight, versatile boards have become an integral part of businesses in the electrical appliance, industrial parts, automotive parts, food and drink, retail and construction sectors.

We believe in being a force for change in our industry, by providing 100% recyclable solutions that make a measurable difference to our clients’ businesses. We are proud to hold the ISO 14001 accreditation for environmental management, with a corporate social responsibility to help our clients become more environmentally aware, whilst offering them the opportunity to generate additional income from the standard cardboard recycling scheme.

PAPER

Virgin or recycled paper sourced from a raw material supplier that has:

GLUE

We have many stringent procedures we adhere to in order to maintain our high level of service, two of which have been at the forefront of the business from the outset; the quality of our products and the passion and skill of all of our workforce. Over the years we have developed and refined all of our products to perform to their best, allowing us to offer innovative, reliable, cost-effective and technically sound products with extremely high sustainability credentials.Combine all of this with the investment in both our technology and our workforce and we have a winning formula that has stood the test of time.

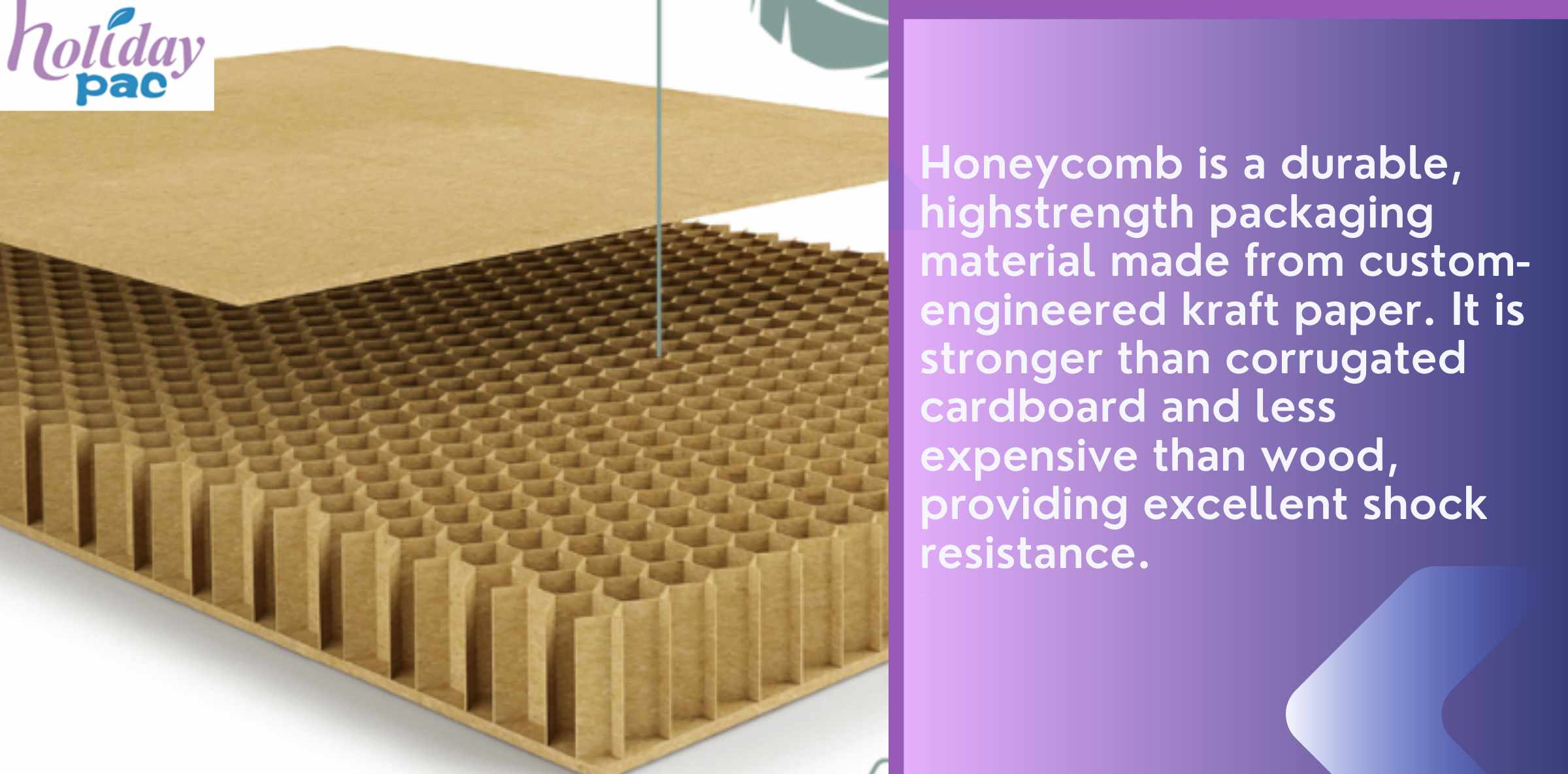

Kraft paper Honeycomb packaging is manufactured using custom-engineered kraft linerboard, a durable high-strength packaging material with cushioning and bracing properties provide resistance to shock and crushing during transit, making it an ideal packaging solution for a variety of applications. Stronger than corrugated cardboard and less expensive than wood, Honeycomb is customizable and provides a cost-effective solution for transportation dunnage, inner and outer product protection as well as the structural foundation for unitized goods. With variable cell sizes and paper combinations along with die-cutting possibilities, Honeycomb paper packaging can be modified to achieve desired strength and configurations to suit any application. In addition, Honeycomb can be treated with specialty finishes and coatings for further customization.

Honeycomb is made by joining individual bands of kraft paper together into a series of continuous hexagonal cells. In most cases, the cells are faced on both sides with similar materials to create an exceptionally strong product.Holidaypac’s honeycomb protective products are an excellent option for a variety of applications to create a customized, and cost-effective solution. Our honeycomb is manufactured in a variety of shapes, sizes and options that are designed specifically for your product needs.

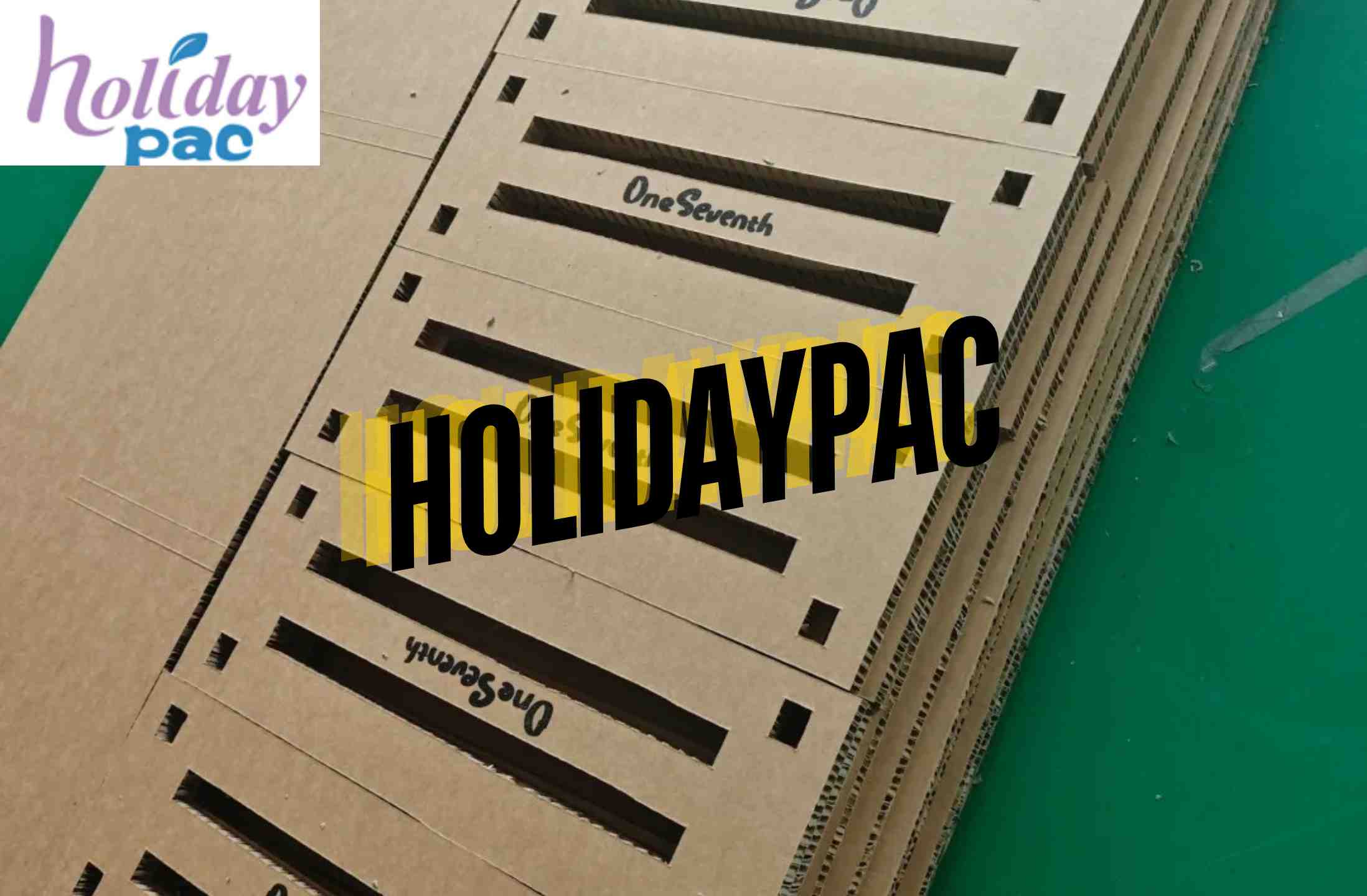

Reverse Slit Score Honeycomb is made by cutting through one facing paper and through the core material and then by cutting the opposite facing paper at another location to create a fan-folding effect in the panel. Single Slit Score is produced the same way but leaves the other facing paper intact to create a folding hinge in the panel.

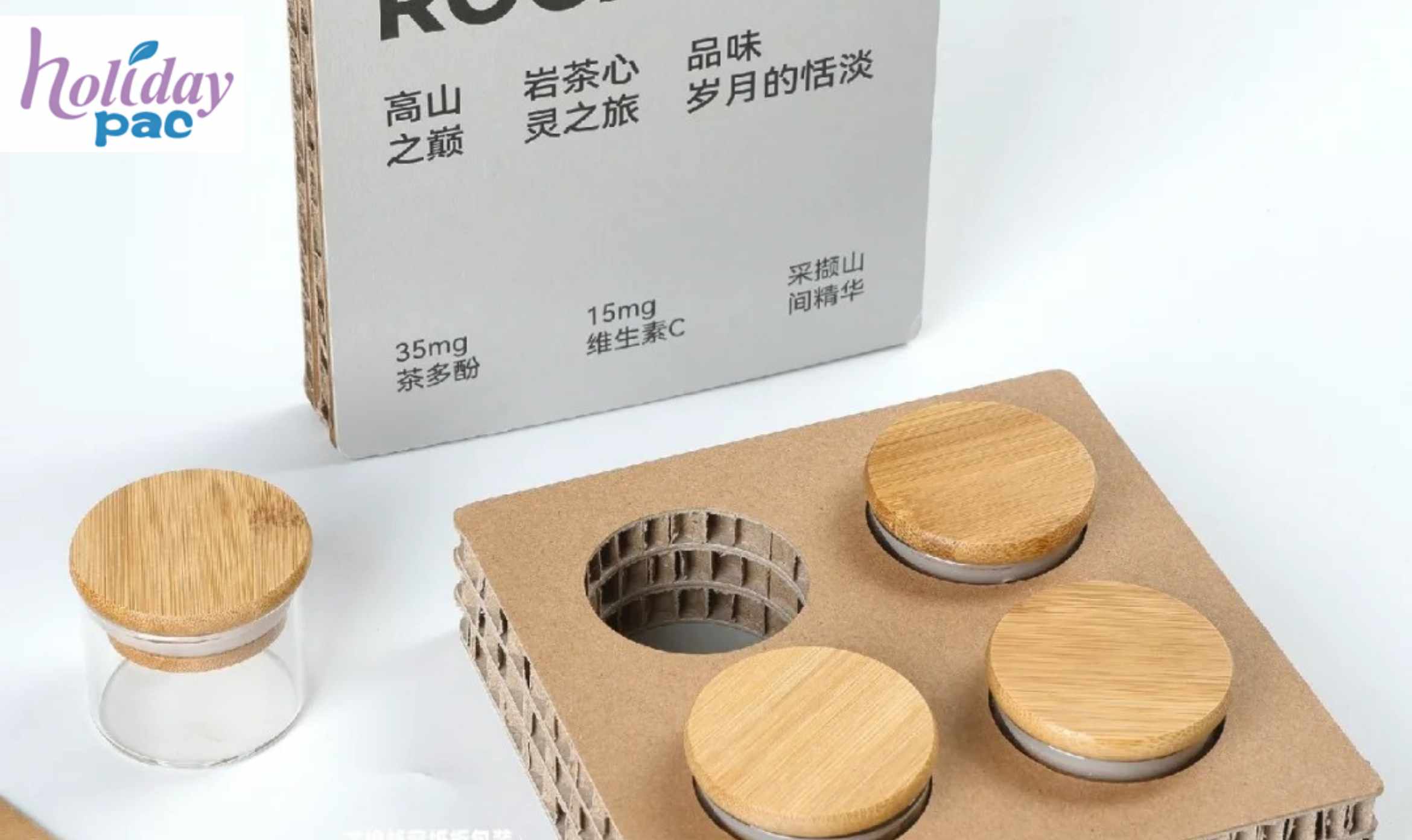

Die-cut Honeycomb is made by producing panels with holes that are cut through the material in the desired shape or thickness. Die-cut panels can be either glued to a flap panel to create a tray for bulk packing or used to surround an item for inner packing.

Contact us for more information by [email protected] or +8618124670856

Links