In 2018, Holidaypac cooperated with MingJiang Packaging Factory and invested in Cambodia, establishing a sub-factory for packaging and sewing bags. Here is the brief information about Holidaypac Cambodia Packaging Factory.

Location: Special Economic Zone Sihanouk, Plov Lum, Smach Dieng Village, Ream Commune, Prey Nop District, Sihanoukville, Cambodia

Factory Size: 6500 sqm land, 4200 sqm floor size.

Number of Employees: 336 total (331 permanent, 11 foreign, 134 migrant)

Currently, we have a total of 334 employees, including 321 production employees and 13 managers, supporting and office staff. All employees are local, directly hired by the factory except 9 Chinese management who are directly hired from China and 321 local workers. The factory established a social compliance policy in place for core implementation such as discrimination policy, child labor, forced labor, wages & benefits, working hours, health & safety, etc.; all the policies and procedures were endorsed by the top management and updated annually. Risk assessment and internal audit were conducted to ensure that a good OSH system is guaranteed with continuous improvement for workers' workplace. The factory management has a positive attitude and commitment to comply with the local law and client’s standards. All NCs were acknowledged and accepted by the factory for further corrective action and sustainability.

Industry: Packaging and Bags

Key Product: Packaging Boxes, Bags, Food Grade Packaging, Boxes and Other Paper-related products

Export Logistics: 100% by sea, using third-party logistics providers

A health and safety factory tour was conducted in all areas of our factory. The factory was clean and tidy. Exit doors were installed in each section and all emergency exits were installed and opened in the outward direction. We had installed a sufficient ventilation system in the production areas. In addition, the temperature of all production areas was acceptable. All exit doors were properly equipped with exit signs and emergency lights. Our factory has installed fire alarm buttons along with user instructions in all sections and the fire alarm system was equipped with battery backup. Fire hoses were installed in the factory with a water reserve tank. The smoke detector is installed in the material and finished goods warehouses. Electrical panels were equipped with inner covers, rubber mats underneath, marked, and electrical lines and cables were put in the duct/tray. Each section was also equipped with first aid kits. Toilets were separated by gender and provided with sufficient supplies. Fire extinguishers were provided in all sections.

The factory had Health & Safety committee members and held monthly meetings to ensure that health and safety in the factory are checked and monitored regularly in accordance with the updated local law and client’s standards. Also, internal assessment and risk assessment have been conducted by the compliance department. Every year, on average, the factory undergoes about 2 - 3 social compliance audits. The factory had Mr. Alan Ooi – CEO responsible for the overall compliance status of the factory.

Policies and procedures on the environment of the facility include the section of general hygiene within the areas, waste storage and management, energy saving, and resource saving. The factory: Mr. Alan Ooi – CEO is responsible for monitoring the environmental manner. The facility designated an area for temporarily storing the wastes. The kitchen waste, industrial solid waste, and chemical wastes were separately stored and collected by an accredited garbage company regularly for disposal as per local law requirements. All wastewater (sanitary) was properly discharged into the public drainage set up by the industrial zone system.

Holidaypac Cambodia Packaging Factory performance ranks in the top percentile of the population and/or has implemented a best practice process.

Holidaypac Cambodia Packaging Factory has comprehensive working hour and wages management processes and procedures in a written manual that support adherence to social compliance requirements and are being properly implemented. Total overtime hours are within allowable limits under applicable law or agreement.

Holidaypac Cambodia Packaging Factory has comprehensive employee safety processes and procedures in a written manual that support adherence to social compliance requirements and are being properly implemented.

Holidaypac Cambodia Packaging Factory has comprehensive emergency preparedness processes and procedures in a written manual that support adherence to social compliance requirements and are being properly implemented.

Holidaypac Cambodia Packaging Factory has comprehensive chemicals management processes and procedures in a written manual that support adherence to social compliance requirements and are being properly implemented.

Holidaypac Cambodia Packaging Factory conducts and/or pays for regular occupational health examinations for employees when applicable.

Holidaypac Cambodia Packaging Factory (including construction projects) has the building permits and/or fire safety permits as per the legal requirements.

Holidaypac Cambodia Packaging Factory has implemented a mechanism/program to identify, evaluate and control employee exposure to physically demanding work, such as manual handling, heavy lifting, highly repetitive tasks, and other physically demanding jobs to prevent work-related injuries.

Holidaypac Cambodia Packaging Factory total working hours during the period specified by the waiver are within allowable limits under the waiver.

Holidaypac Cambodia Packaging Factory employment practice procedures (forced labor, freedom of association, employment contracts, discipline, harassment & abuse) are in place.

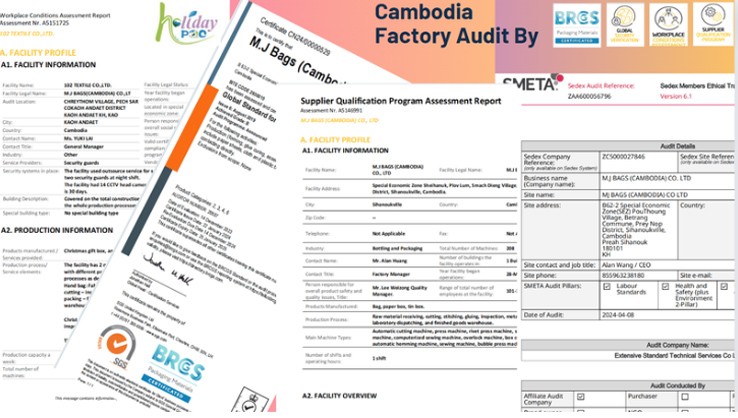

Holidaypac Cambodia Packaging Factory is certified by BRC, WCA, SEDEX, SQP, and FSC. This recognition underscores the company's commitment to maintaining high standards of quality, social responsibility, and environmental sustainability. BRC certification ensures food safety and quality, while WCA (Workplace Conditions Assessment) guarantees fair labor practices and safe working conditions. SEDEX (Supplier Ethical Data Exchange) and SQP (Supplier Qualification Program) affirm ethical business practices and supplier quality management, respectively. Finally, FSC (Forest Stewardship Council) certification highlights the factory's dedication to responsible forestry practices. At Holidaypac Cambodia, these certifications are more than just accolades; they represent an ongoing promise to customers, employees, and the planet. The factory continues to innovate and improve its processes, striving to set new benchmarks in the industry. Through a combination of cutting-edge technology, skilled craftsmanship, and unwavering ethical standards, Holidaypac Cambodia is poised to lead the way in sustainable manufacturing.

Links