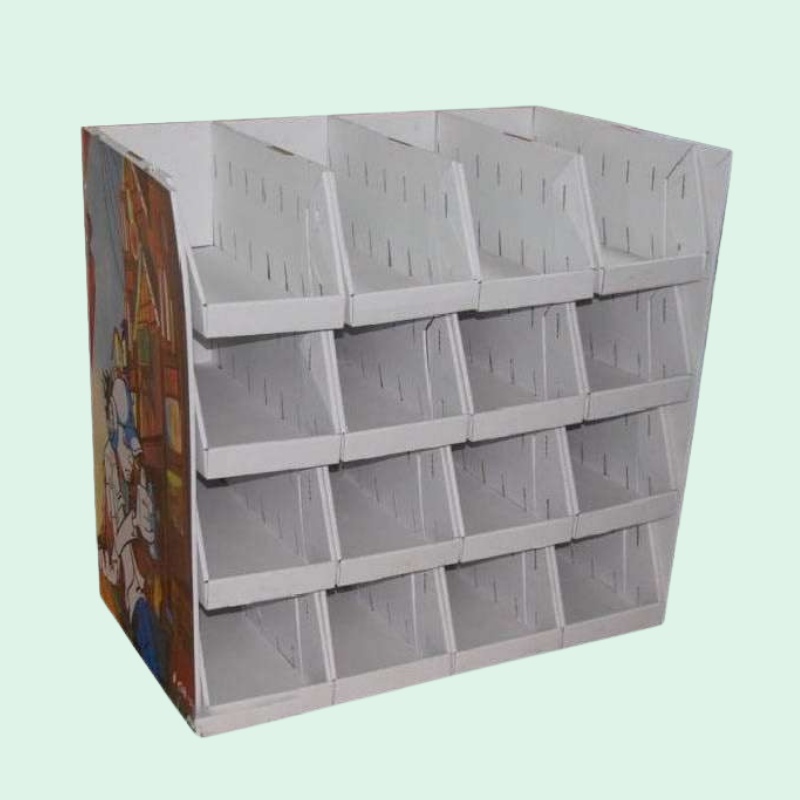

Generally , the display racks for retail stores will take at least 1 months from composition to shipment. Some projects will takes a year or half to complete. Nothing else for the reason, because the what is the production process is what process of products’ search and development. there are too many factors to consider. The design phase includes appearance and structure design. The appearance is the first step, the second one is structure. Today, we would like to clarify the structure design in the assembly process which also an essential step.

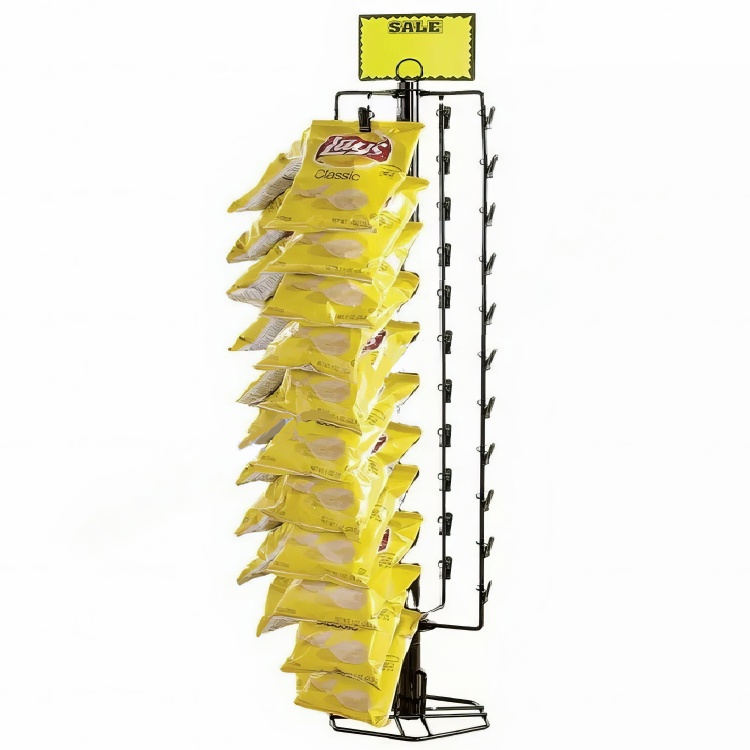

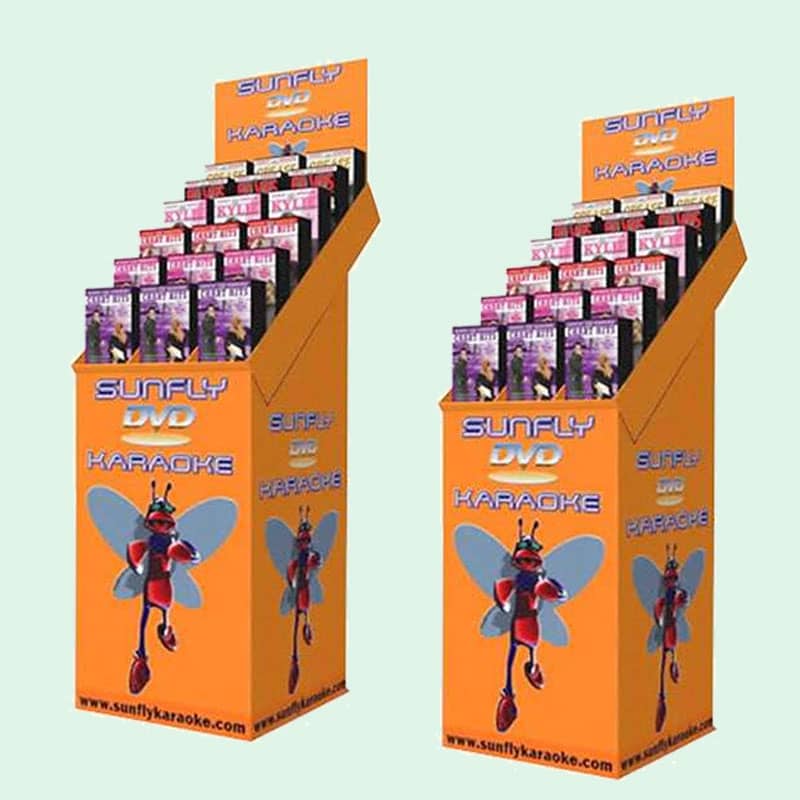

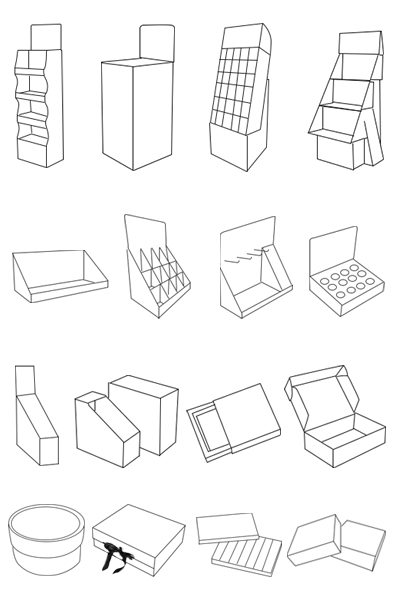

Firstly, let’s see why the display racks for retail stores need to assemble. From factory order production to shipment to buyers all over the country, the packaging way has no single standard, because the difference of compression degree affected by volume, material. Transportation distance and packaging way are the key factors that affect transportation costs. Especially for some large display racks, the cost rate for transportation is increasing from assemble to shipment. At this time, the designer needs to devise the display racks as easily assemble structure. And Shipment with split packaging way.

However, why does the difficulty of assembling the display racks for retail stores affect the utilization rate of customers? On the one hand, it can assemble fast and save the cost of time and manpower, so that the customers will be more satisfied. On the other hand, the harder assmble, the more parts racks need. Furthermore, different size of the screw and complicated instructions make customers confused, much less to the ordinary people who haven’t trained in the field. If the assemble of display racks cost too much, I think the fate of this display rack will end in the warehouse. Since 2005, we have focused on the design and production of display frames. We are strong experts and experienced experts.