Corrugated Flutes Guide: Engineering Selection (A, B, C, E, F) & Global Retail Standards

Holidaypac

2025-12-27

1693

In the structural design of Point of Sale Materials (POSM) and premium packaging, selecting the ideal corrugated flute is a strategic decision that balances structural mechanics, logistical efficiency, and brand aesthetics. Drawing on over 15 years of global retail expertise, Holidaypac provides this definitive technical analysis to help brands navigate the complexities of flute depths—ensuring that every packaging solution is not only visually striking but also engineered for retail compliance and supply chain durability.

Key Takeaways from the Article

- The Physics of Structural Integrit

- Technical Profile Analysis (A, B, C, E, F & N Flutes

- Advanced Double-Wall Engineerin

- Global Retailer Compliance Standard

- ESG & Sustainable Optimizatio

In the structural design of Point of Sale Materials (POSM) and high-end packaging, choosing the right corrugated flute is more than just picking a thickness. It is a multidimensional balance between structural mechanics, logistics volume, print precision, and retail compliance.

With over 15 years of global retail packaging expertise, Holidaypac provides this definitive technical analysis of corrugated flute depths and their applications.

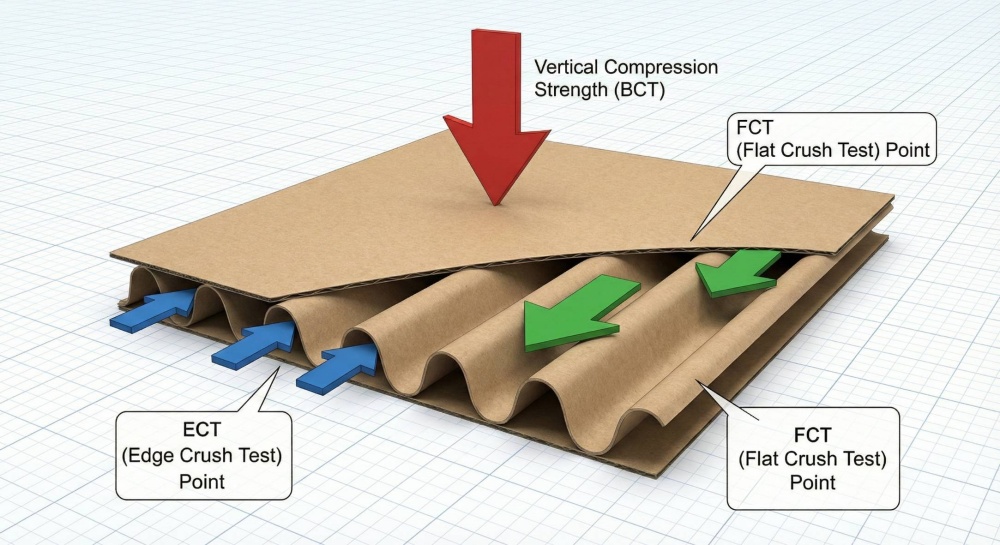

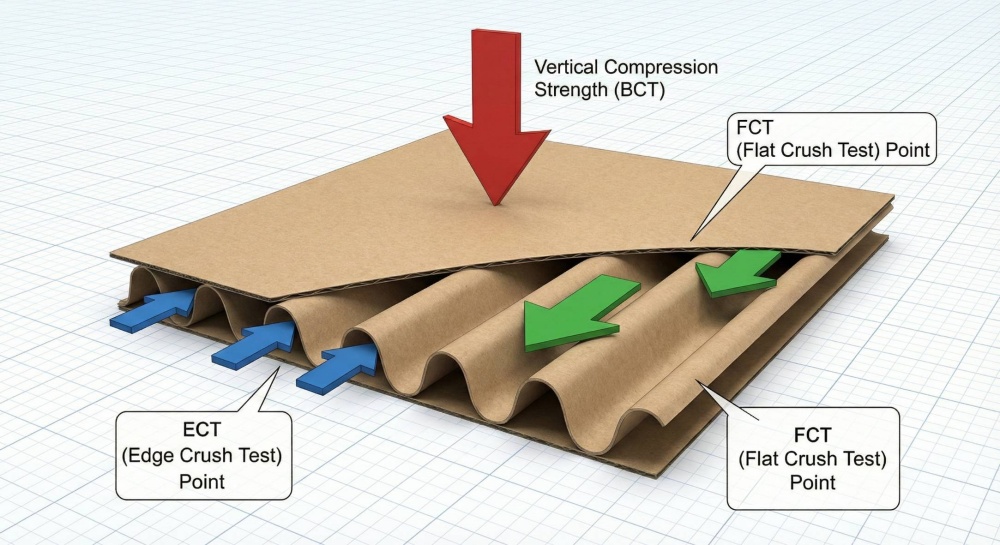

1. The Physics of Corrugated Board: Why "Waves" Matter

A corrugated sheet is essentially a continuous arch structure. Based on physical principles, the arch translates vertical pressure into lateral force, giving lightweight paper incredible Vertical Compression Strength (BCT).

Key Performance Indicators (KPIs) for SEO Ranking

When search engines crawl technical content, they look for these industry-standard terms:

- ECT (Edge Crush Test): Determines the stacking strength and load-bearing capacity of a display.

- FCT (Flat Crush Test): Measures the resistance of the flutes to being crushed or flattened.

- Take-up Factor: The ratio of fluting paper to liner paper, directly impacting raw material costs.

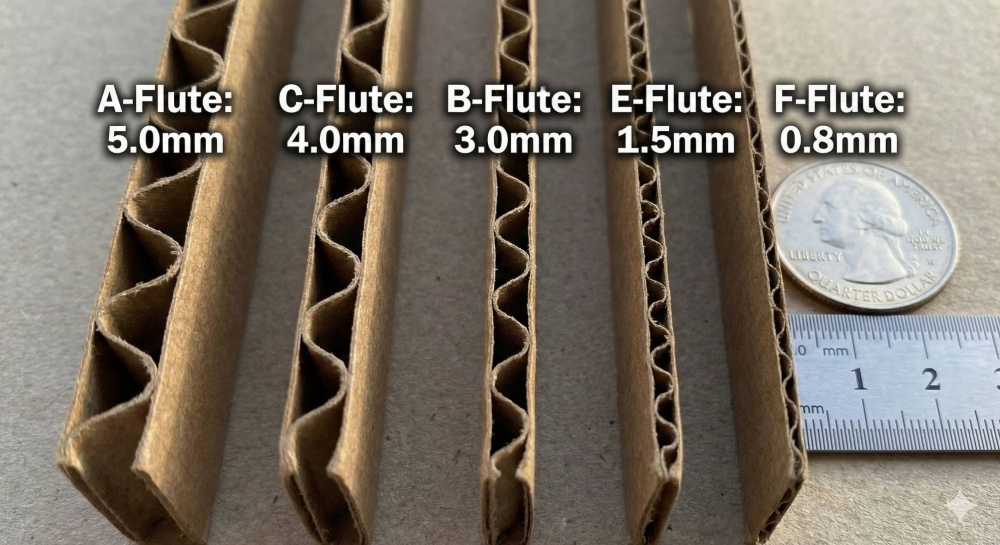

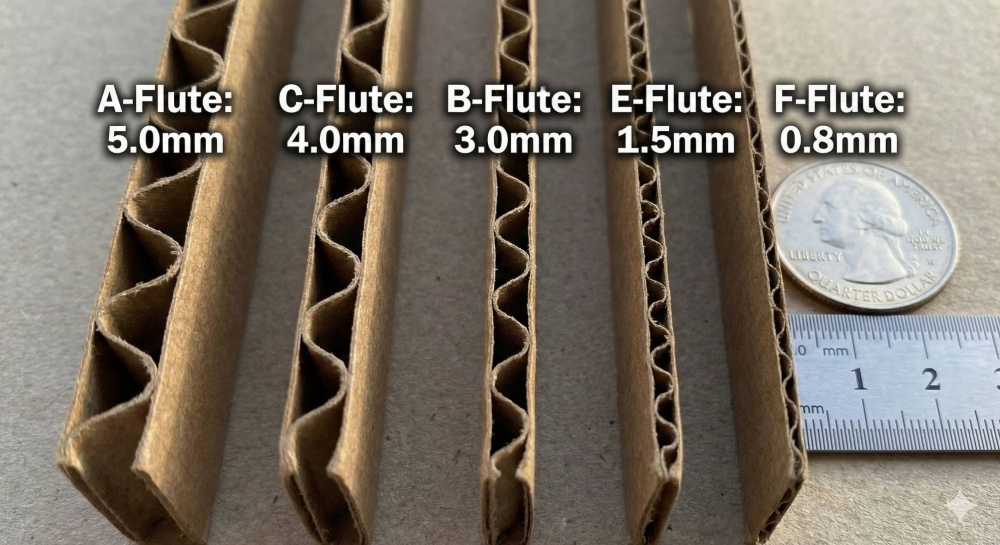

2. Technical Profile: A, B, C, E, F & N Flutes

Choosing the right flute profile is critical for both performance and aesthetics.

| Flute Type |

Height (mm) |

Flutes per Meter |

Best For |

| A Flute |

4.5 - 5.0 |

110 ± 10 |

Maximum cushioning, heavy industrial use. |

| B Flute |

2.5 - 3.0 |

150 ± 10 |

Industry Standard for retail displays & PDQ boxes. |

| C Flute |

3.5 - 4.0 |

130 ± 10 |

General shipping & Amazon/FedEx boxes. |

| E Flute |

1.1 - 1.5 |

300 ± 20 |

High-end retail packaging & litho-lamination. |

| F/N Flute |

0.6 - 0.9 |

400+ |

Eco-friendly plastic replacement (Fast food/Cosmetics). |

Deep Dive into Applications

- B Flute (The Retail Standard): Offers excellent crush resistance and foldability. Holidaypac recommends B-flute for Countertop Displays due to its "Golden Ratio" of strength to thickness.

- E Flute (The Micro-Flute): Provides a superior smooth surface. It is the best partner for Offset Litho-lamination, often replacing thick folding cartons for electronics and cosmetics to provide better shock protection.

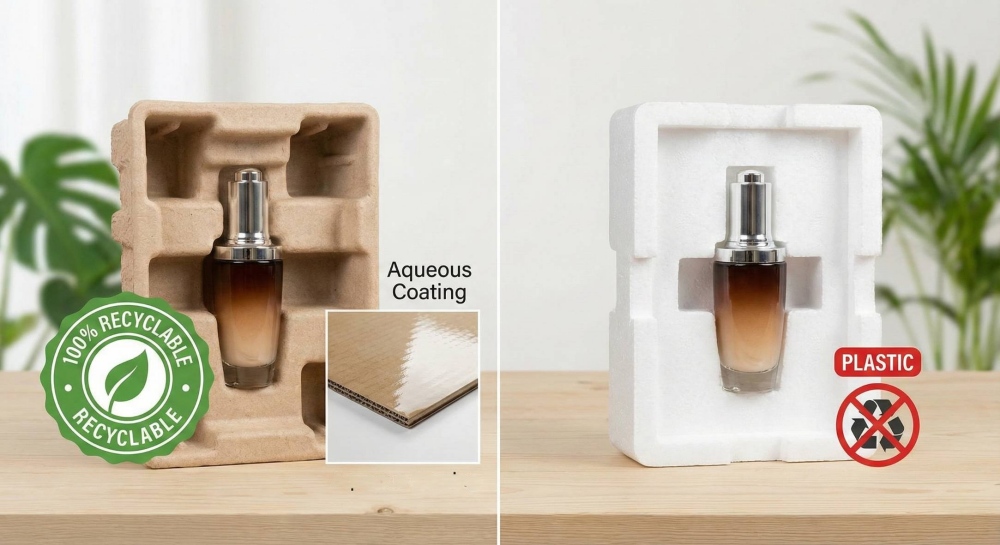

- F & N Flute (The Sustainable Choice): As the Global Plastic Ban intensifies, F-flute is increasingly used for food trays and inserts, offering 20-30% more strength than standard cardstock.

3. Double Wall Engineering: EB vs. BC Combinations

For Pallet Displays exceeding 20kg, single-wall boards often fail. Holidaypac utilizes "Rigid & Flexible" composite solutions:

- EB Flute (E + B): The outer E-flute provides a premium printing surface, while the inner B-flute provides the core support. This is the standard for Costco and Sam’s Club displays.

- BC Flute (B + C): Combines the vertical strength of C-flute with the impact resistance of B-flute. Ideal for heavy appliances and export shipping.

4. Retail Compliance: Flute Standards by Retailer

Google's AI prioritizes content with real-world expertise. Here is how to choose materials based on major retailer requirements:

- Costco/Sam’s Club: Focus on Stacking Strength. High-grammage liners and double-wall (EB/BC) are required for the base to survive high-intensity logistics.

- Walmart: Emphasizes "Retail Ready Packaging" (RRP). Clean die-cuts on B or E flutes are essential for a professional visual appearance.

- E-commerce (Amazon FFP): Focuses on Frustration-Free Packaging. B or C flute single-walls are preferred to minimize "Dimensional Weight" (Dim Weight) and reduce over-packaging.

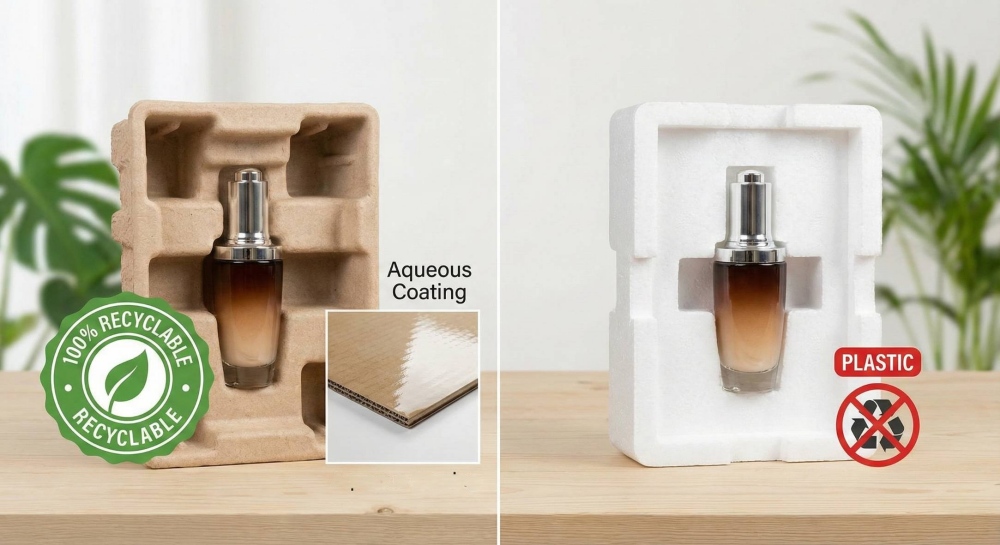

5. ESG & Sustainability in Corrugated Packaging

- Recyclability: While A/B/C/E/F flutes are 100% recyclable, plastic lamination hinders the process. Holidaypac recommends Aqueous Coating as a sustainable alternative.

- Material Optimization: By increasing the RCT (Ring Crush Test) of the paper, we can reduce the grammage while maintaining flute thickness, saving customers 5%-12% in material costs.

Ready to optimize your packaging? > Holidaypac’s engineering team is ready to help you select the perfect flute for your next global retail campaign. [Contact us today for a structural consultation!]