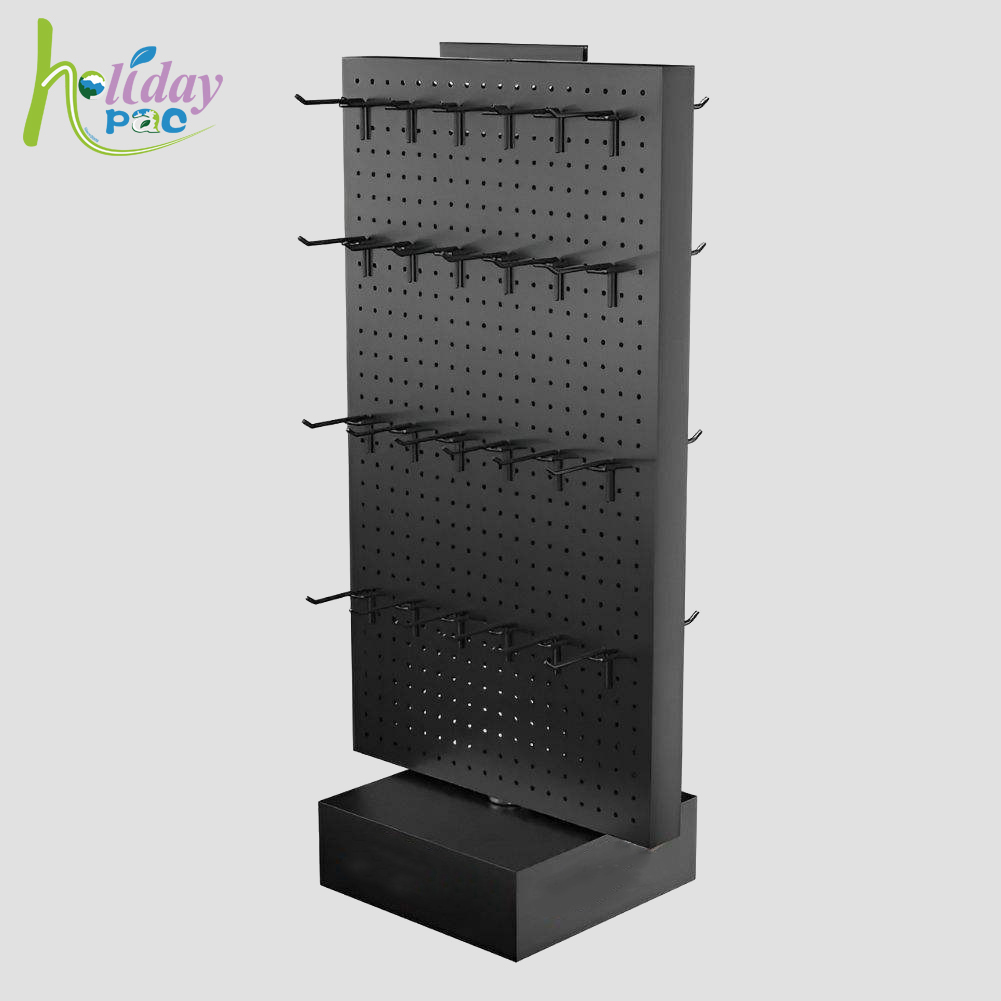

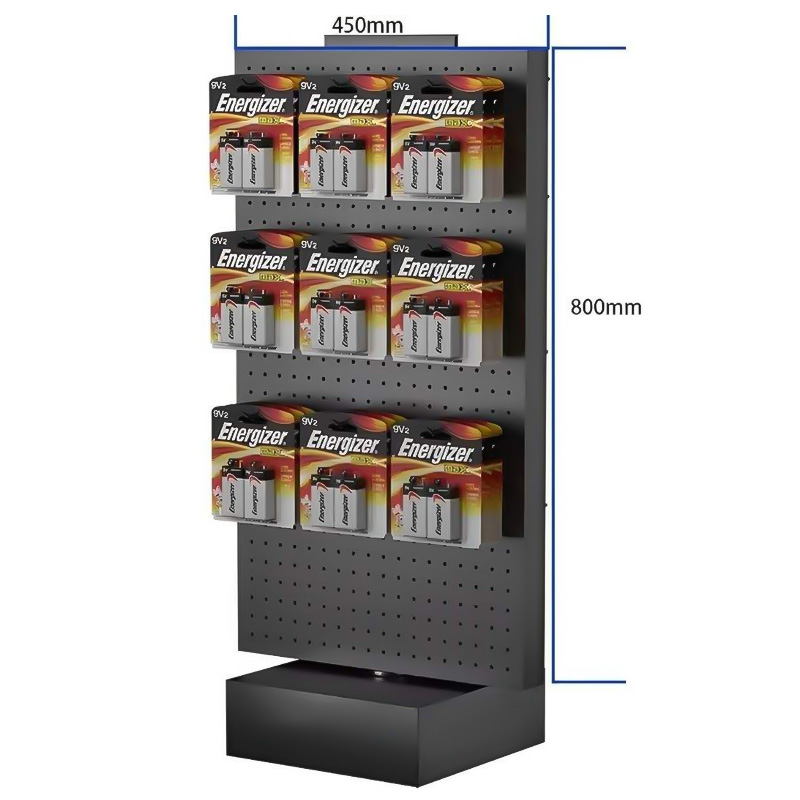

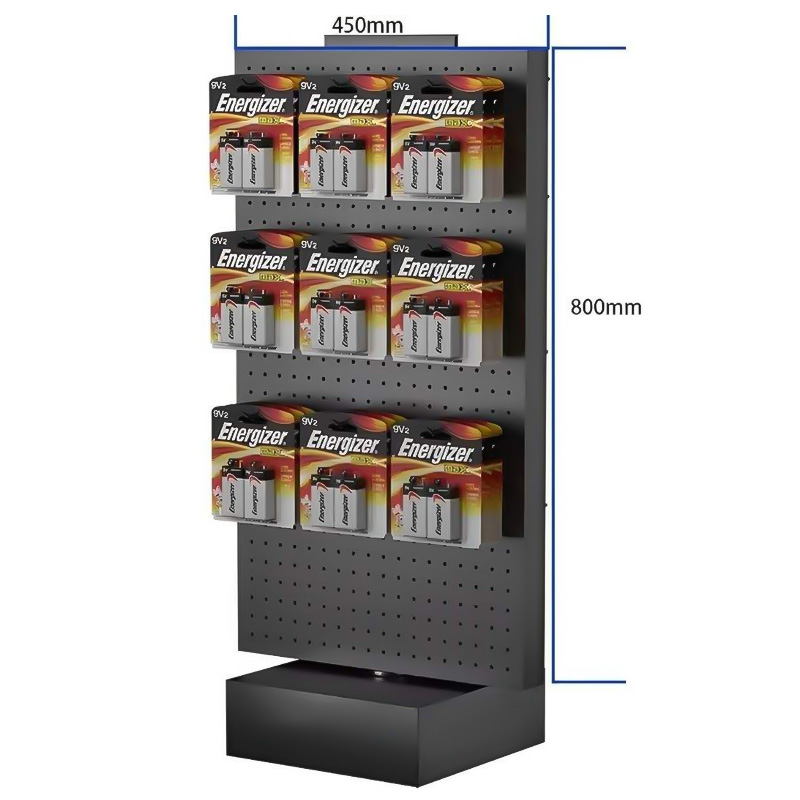

Upgrade your display solutions with our Black Metal Pegboard Display Rack, designed to meet all your retail and organizational needs.

Build a brand high-quality display shelf with strength

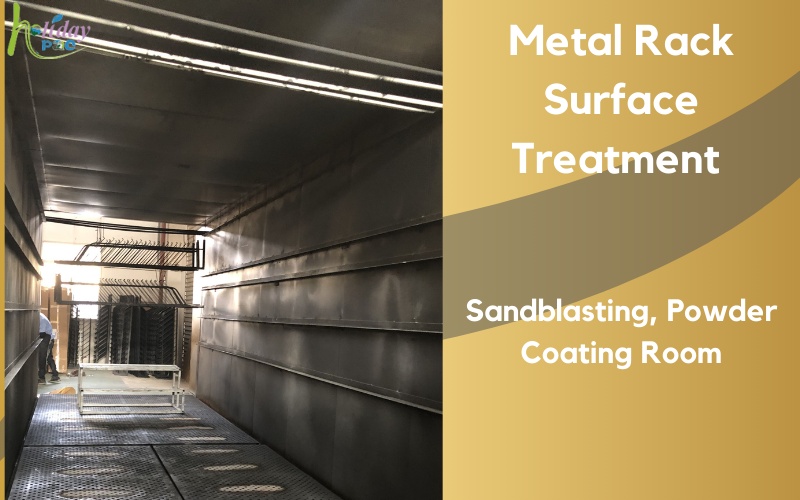

Professionals of advanced production equipment in large-scale production workshops

5 Dali let you choose me

|

|

|

|

|

|

| Thickened panel |

Layer load is 150-200 Jin. |

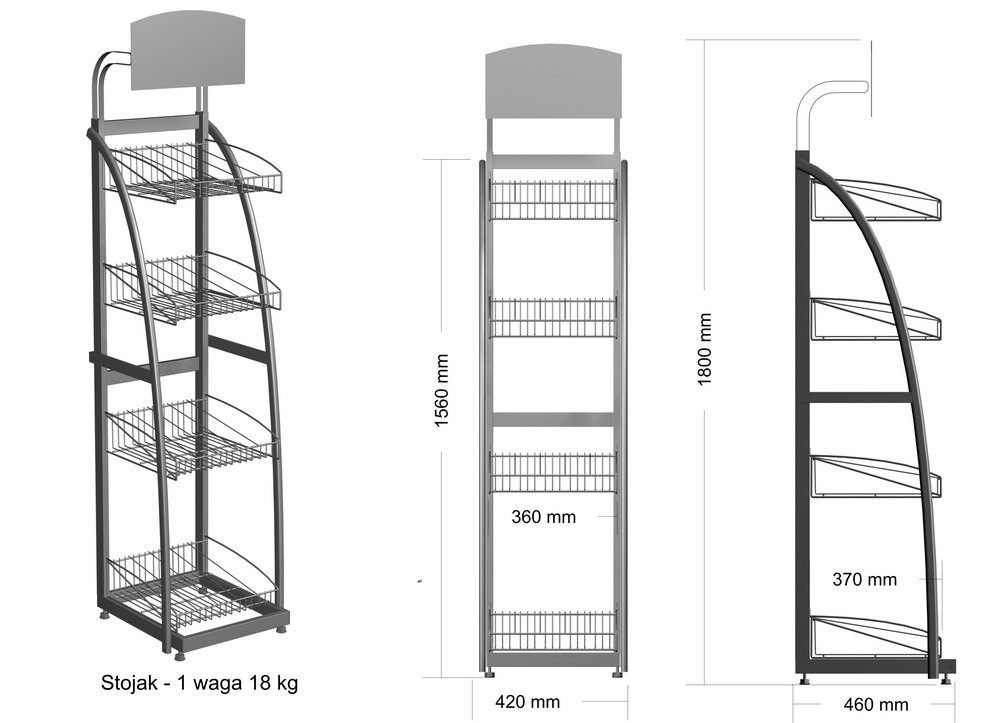

Bold tubing | Strong load bearing | Ingenuity design |

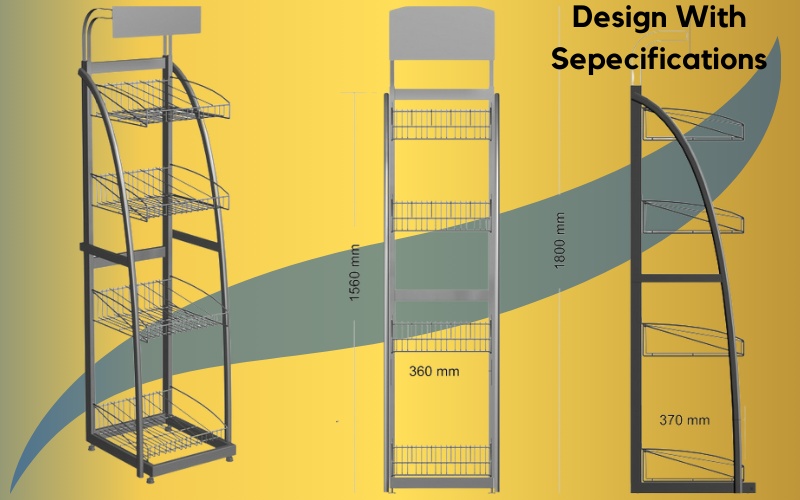

Professional design service

According to our actual situation, size and scale, we will provide a sketch of the transaction,

and we will design the CAD drawing plan for free.

|

|

|

|

| Customized floor plan | Three-dimensional effect rendering | Take a real shot at the scene. |

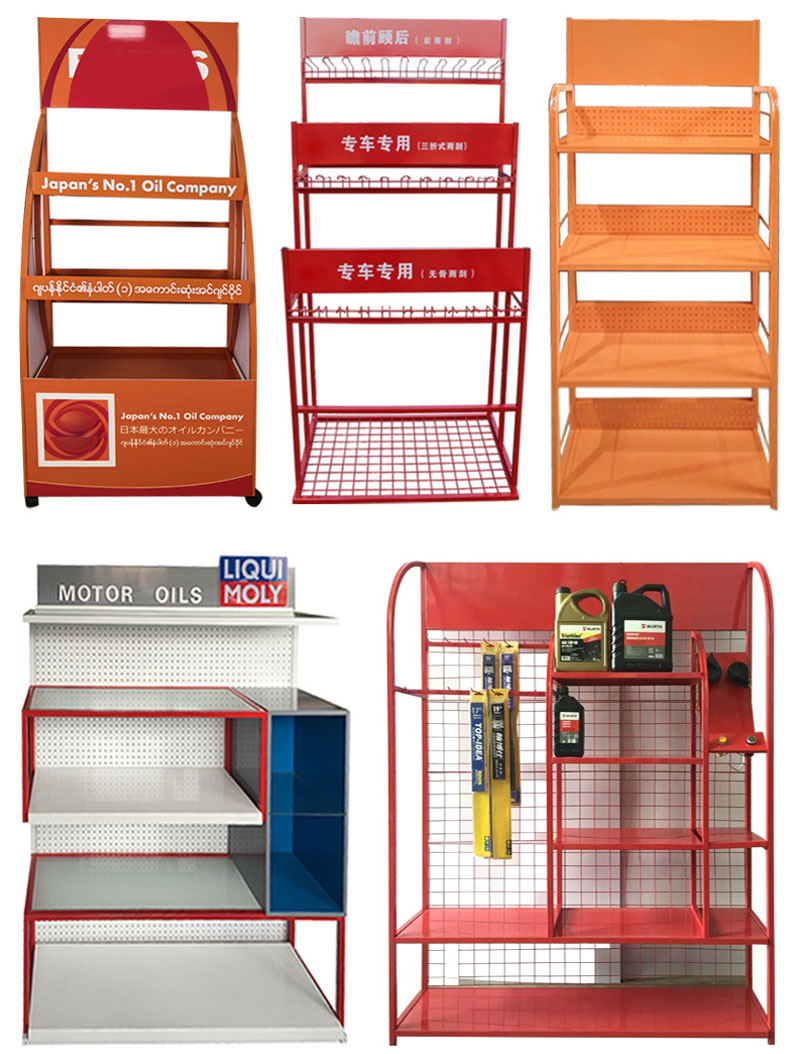

More styles to choose from

What Brands Holidaypac Cooperated With all over the world?

Holidaypac produce many displays go into Coles, Costco, Woolworths, Sam's club,

Walmart, and the brands as Energizer, carbury,Mentholatum, Nescafe, Sensodyne, Disney Etc.

How Holidaypac Manage the Company and Service the Clients?

All our people are working for many years in Holidaypac, they are keen manage person

in HolidayPac company with different postion,Any question for packing and display solution,

our experts will reply you and give you suggestions base on our skills and experienced systerm!

Pls contact us by email tiger@holidaypac.com or by phone +86 181 2467 0856 anywhere any time,

Our professional team will answer you 24 hours 7days.

Links