The Custom Pop-Up Spring-Loaded Metal Steel Floor Stand Beverage Display offers a revolutionary approach to showcasing beverages in retail spaces. Utilizing an advanced Automatic Lifting System, this display ensures that products are always visible and accessible to customers. As each item is taken, the spring-loaded mechanism smoothly lifts the next, providing a dynamic and engaging experience that keeps shoppers intrigued and encourages interaction with the product.

Designed with high-volume shopping in mind, this floor stand beverage display is capable of holding large quantities of products, making it an excellent solution for bulk sales. Customers can easily purchase in larger quantities without the need to search through messy stacks. The automatic lifting feature ensures that the next item is always within reach, simplifying the shopping experience and making it more efficient for both consumers and store staff.

Customization is key when it comes to branding, and the Custom Pop-Up Beverage Display allows for tailored structural designs and printing to suit your brand’s identity. From vivid CMYK printing that brings your brand to life to unique design elements that fit the retail environment, this display stands out from the competition. Whether you need a compact display for smaller spaces or a larger structure for high-traffic areas, the flexibility of this design ensures a perfect fit for your brand's needs.

Whether you're displaying lightweight mini bottles or heavy full-size cans, this metal steel display is designed to handle varying product weights. The spring-loaded system automatically adjusts to the load, providing consistent performance for both light and heavy products. This versatility makes the display suitable for a wide range of beverage types, ensuring that every item is presented at its best without sacrificing stability or functionality.

In addition to its high functionality, the Custom Pop-Up Beverage Display is crafted from recyclable corrugated cardboard, making it an environmentally friendly choice for businesses committed to sustainability. Combined with a durable metal steel frame, this display offers both strength and eco-conscious design. Retailers can reduce their environmental footprint while benefiting from the robust, long-lasting nature of the display.

The integration of an Automatic Lifting System in this beverage display not only elevates product presentation but also improves operational efficiency. The spring-loaded mechanism minimizes the need for manual restocking, automatically positioning products at the forefront for easy access. This practical innovation saves time and labor, allowing store staff to focus on other important tasks, while ensuring that customers always have a well-organized and visually appealing selection to browse.

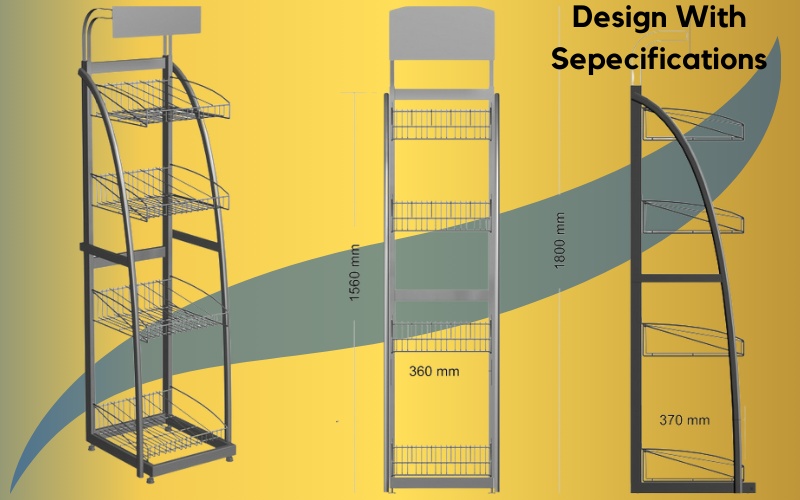

1. Design and Specifications:

The process begins with the design phase, where engineers and designers collaborate to create detailed blueprints and specifications for the metal rack. The design must meet the functional requirements, including dimensions, weight capacity, and aesthetic considerations

2. Material Selection:

Selecting the appropriate materials is crucial for ensuring the durability and strength of the metal rack. Common materials include various grades of steel or aluminum,depending on the intended use and load-bearing requirements.

3. Cutting and Shaping:

Once the materials are selected, they are cut and shaped according to the design specifications. This step often involves using advanced machinery such as CNC cutters, laser cutters, or hydraulic shears to achieve precise dimensions and shapes.

4. Forming and Bending:

The cut metal pieces are then formed and bent into the required shapes. Techniques such as press braking, rolling, and stamping are employed to create the structural components of the rack.

5. Welding and Assembly:

The formed components are welded together to create the frame and structure of the metal rack. Skilled welders use various welding techniques, such as MIG, TIG, or spot welding, to ensure strong and durable joints. After welding, the components are assembled to create the final structure.

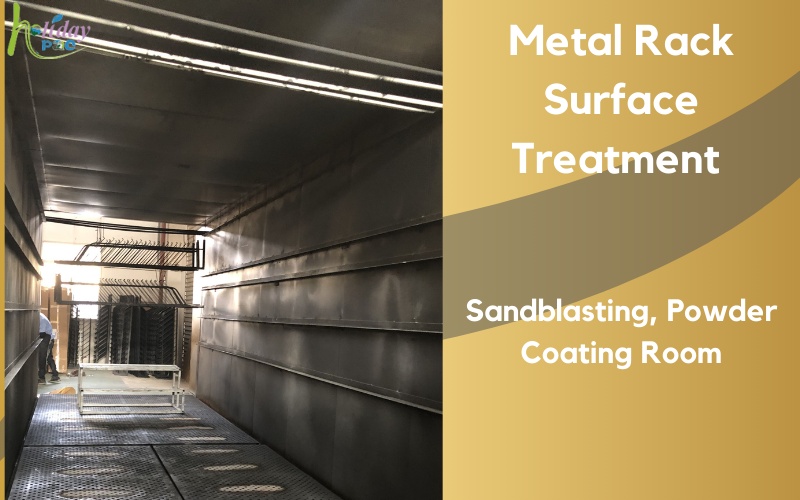

6. Surface Treatment:

To enhance the durability and appearance of the metal rack, surface treatments are applied.This may include processes like sandblasting, powder coating, or galvanizing, which protect the metal from corrosion and wear, and provide a smooth, attractive finish.

7. Quality Control:

Rigorous quality control checks are conducted throughout the production process to ensure that the metal rack meets all design specifications and quality standards. This includes inspecting welds, verifying dimensions, and conducting load-bearing tests.

8. Packaging and Shipping:

Once the metal racks pass quality control, they are carefully packaged to prevent damage during transportation. The racks are then shipped to the customer or distribution centers,ready for use in various applications.

By adhering to this meticulous production flow, manufacturers ensure that each metal rack is built to the highest standards of quality, durability, and functionality, meeting the specific needs of their clients.

What Brands Holidaypac Cooperated With all over the world?

Holidaypac produce many displays go into Coles, Costco, Woolworths, Sam's club,

Walmart, and the brands as Energizer, carbury,Mentholatum, Nescafe, Sensodyne, Disney Etc.

How Holidaypac Manage the Company and Service the Clients?

All our people are working for many years in Holidaypac, they are keen manage person

in HolidayPac company with different postion,Any question for packing and display solution,

our experts will reply you and give you suggestions base on our skills and experienced systerm!

Pls contact us by email tiger@holidaypac.com or by phone +86 181 2467 0856 anywhere any time,

Our professional team will answer you 24 hours 7days.

Links